Understanding the Role of Curtains in Interior Design

Curtains have evolved far beyond simple window coverings.

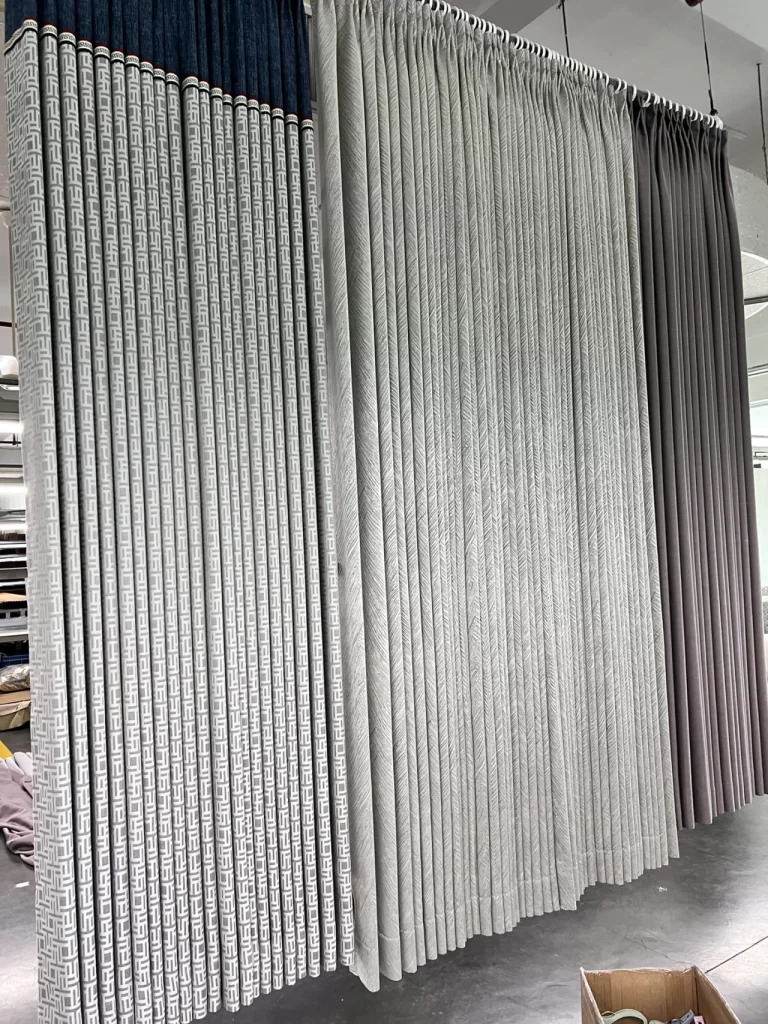

In modern architecture and interior decoration, they play a vital role in light control, thermal insulation, acoustic balance, and visual aesthetics.

Whether for homes, hotels, offices, or commercial projects, curtains must combine style and function while matching the personality of the space.

Professional curtain factories today emphasize fabric innovation, eco-friendly production, and customization options to serve global markets with high-quality window solutions.

Different Curtain Materials and Their Characteristics

Choosing the right fabric is essential for achieving the desired look and performance.

Below is a comparison table showing the most commonly used curtain materials, their key features, and recommended applications.

| Material Type | Main Features | Advantages | Recommended Use |

|---|---|---|---|

| Polyester | Lightweight, wrinkle-resistant, affordable | Easy maintenance, long-lasting color | Homes, offices, apartments |

| Cotton Blend | Soft texture, breathable, natural feel | Eco-friendly, suitable for dyeing and printing | Living rooms, bedrooms |

| Jacquard Fabric | Woven decorative patterns | Elegant texture, durable and premium look | Hotels, luxury interiors |

| Velvet | Thick and soft with rich color depth | Excellent insulation and sound absorption | Theaters, hotels, bedrooms |

| Sheer Voile | Transparent and airy | Enhances light diffusion, adds elegance | Living rooms, cafes, event halls |

| Blackout Fabric | Triple-layered or coated textile | Blocks 90–100% sunlight, thermal control | Bedrooms, offices, hotels |

Each material type offers unique advantages depending on the style preference, budget, and functional requirement of the project.

A professional curtain manufacturer can recommend suitable fabrics based on local climate, light orientation, and installation purpose.

Curtain Manufacturing Process Overview

Modern curtain production involves multiple stages, each requiring precision and expertise:

- Fabric Selection and Testing – Fabrics are chosen based on texture, colorfastness, and functionality.

- Cutting and Pattern Design – Tailored according to window measurements and style requirements.

- Sewing and Stitching – Performed by skilled technicians to ensure accurate seams and elegant finishes.

- Accessory Integration – Hooks, eyelets, tracks, and linings are added as per project needs.

- Final Inspection and Packing – Every curtain is checked for defects, color accuracy, and size consistency before shipment.

These steps ensure that each curtain not only meets design expectations but also provides durability and performance over time.

Customization and OEM Curtain Services

To meet the needs of global buyers, many factories provide OEM and ODM curtain services.

Clients can customize the following aspects of production:

- Fabric composition and texture

- Curtain dimensions and pleat styles

- Lining types (thermal, blackout, soundproof)

- Color matching and print patterns

- Packaging and private labeling

Such flexibility allows interior designers, wholesalers, and distributors to offer unique collections that reflect their market trends and branding strategy.

Applications Across Different Industries

Curtains are widely used in diverse environments, including:

- Residential Spaces: Living rooms, bedrooms, kitchens, and balconies

- Hospitality Projects: Hotels, resorts, restaurants, and lounges

- Commercial Offices: Boardrooms, meeting spaces, and lobbies

- Event Venues: Stages, exhibitions, and conference halls

- Healthcare Facilities: Clinics and hospitals requiring privacy and cleanliness

Each industry demands specific performance characteristics, such as fire resistance, light control, or acoustic insulation, which can be customized during manufacturing.

Sustainability in Curtain Production

The modern textile industry is shifting toward eco-friendly and energy-saving practices.

Curtain factories are increasingly adopting:

- Recycled polyester yarns

- Water-based dyes and low-impact printing methods

- Energy-efficient production equipment

- Waste reduction and recyclable packaging

These sustainable approaches not only protect the environment but also improve the long-term value of curtain products.

Global Cooperation Opportunities

With growing demand from Europe, North America, the Middle East, and Asia, professional curtain manufacturers are expanding their export capabilities.

Factories with integrated production systems and international certifications are preferred by importers who require reliable quality, timely delivery, and competitive pricing.

Building long-term partnerships with experienced manufacturers helps global buyers maintain consistent supply and product innovation.

Get in Touch for Professional Curtain Solutions

If you are searching for a trusted curtain manufacturer providing custom design, OEM/ODM services, and full project support,

we welcome your inquiry.

📩 Contact us today to discuss your project requirements, request samples, or get a quotation for curtain production.

Article link:https://www.vlefooena.com/comprehensive-guide-to-curtain-materials-and-manufacturing-for-modern-spaces/

No reply content