In the premium packaging industry, elegance, structure, and customization define how a product is perceived by global consumers. For brands competing in international markets, packaging is no longer just a protective container—it is a critical element of brand identity and value communication. An elegant rigid gift box factory with custom printing solutions plays a vital role in helping brands deliver a refined and memorable presentation.

This article provides a detailed overview of elegant rigid gift boxes, focusing on structural advantages, material selection, custom printing techniques, manufacturing processes, export standards, and real feedback from international buyers.

The Role of Elegant Rigid Gift Boxes in Global Branding

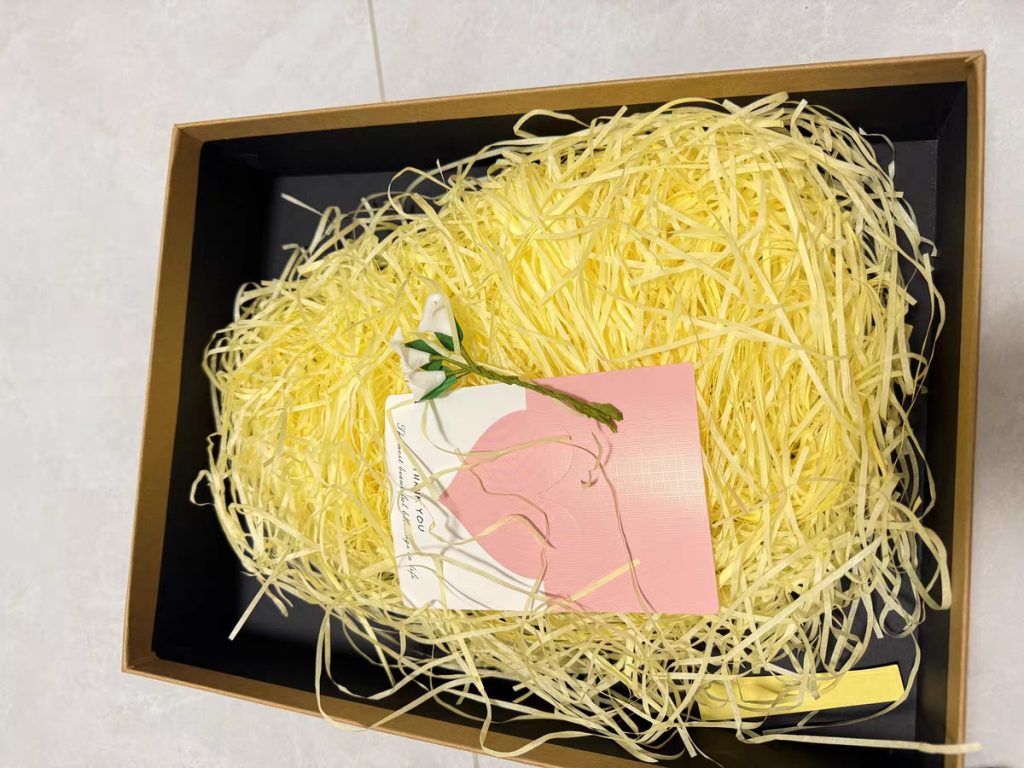

Rigid gift boxes are widely recognized as a symbol of quality and luxury. Their solid construction and refined appearance make them a preferred choice for high-end products across multiple industries.

Elegant rigid gift boxes are commonly used for:

- Luxury gift sets

- Jewelry and accessories

- Cosmetics and skincare products

- Perfumes and fragrances

- Corporate and promotional gifts

- Premium food and confectionery

The combination of strength and aesthetics allows brands to present their products with confidence in both retail and e-commerce environments.

What Makes a Rigid Gift Box “Elegant”

Elegance in packaging is achieved through thoughtful design, high-quality materials, and precise craftsmanship.

Clean Structure and Proportions

Rigid gift boxes maintain sharp edges and stable shape, creating a clean and professional appearance that reflects product value.

Premium Surface Finishes

Elegant finishes such as matte lamination, soft-touch coating, and textured paper elevate the tactile experience and visual appeal.

Balanced Design Language

Minimalist layouts, refined patterns, and carefully placed logos contribute to a sophisticated overall look.

Materials Used in High-End Rigid Gift Boxes

Material selection directly affects durability and appearance. Elegant rigid gift boxes are typically produced using:

- High-density greyboard (1000gsm–2000gsm) for strong structure

- Art paper, specialty paper, or textured paper for outer wrapping

- Matte, soft-touch, or anti-scratch lamination

- EVA foam, velvet, or cardboard inserts for interior protection

These materials ensure the box remains intact during shipping while maintaining a premium presentation.

Custom Printing Solutions for Rigid Gift Boxes

Custom printing is essential for brand differentiation in global markets. A professional rigid gift box factory offers a wide range of printing and finishing options.

Printing Techniques

- Offset printing for sharp images and consistent colors

- Pantone color matching for brand accuracy

- Full-color CMYK printing

Decorative Finishes

- Gold, silver, or metallic foil stamping

- Embossed and debossed logos

- Spot UV highlights for visual contrast

Surface Protection

- Lamination to prevent scratches and moisture damage

- Coatings designed for long-distance export shipping

These solutions allow brands to create packaging that is both visually striking and durable.

Customization Options for International Buyers

Elegant rigid gift boxes can be fully customized to meet different market requirements.

Box Size and Structure

- Custom dimensions based on product specifications

- One-piece lift-off lid or drawer-style designs

- Reinforced corners for added strength

Interior Packaging

- Precision-cut foam inserts

- Velvet or fabric lining for luxury products

- Paperboard inserts for eco-friendly solutions

Branding Details

- Logo placement customization

- Minimalist or decorative artwork styles

- Seasonal or limited-edition designs

Manufacturing Process for Export-Grade Rigid Gift Boxes

A standardized production workflow ensures consistent quality for international orders:

-

Design Confirmation and Sampling

Structural drawings and samples are approved before mass production. -

Material Cutting and Wrapping

Greyboard is cut precisely and wrapped with printed paper. -

Manual Assembly

Boxes are assembled carefully to ensure alignment and strength. -

Printing and Finishing

Custom printing and decorative finishes are applied with quality checks. -

Final Inspection and Packing

Finished boxes are inspected and packed for export shipment.

Export Standards and Quality Control

To meet global market expectations, elegant rigid gift boxes (for export) must comply with strict quality standards:

- Clean edges and strong adhesion

- Consistent color across large quantities

- Structural stability under stacking pressure

- Moisture-resistant packing for sea freight

- Export-grade outer cartons

These measures reduce shipping risks and enhance customer satisfaction.

Applications Across Global Industries

Elegant rigid gift boxes are widely used across multiple sectors:

- Beauty and Skincare – Premium shelf presentation

- Jewelry and Watches – Secure and refined packaging

- Food and Beverage – Gift-ready packaging for festivals

- Corporate Gifting – Professional brand representation

- Luxury E-commerce – Enhanced unboxing experience

Sustainability and Eco-Friendly Packaging Options

Modern global buyers increasingly prioritize sustainability. Rigid gift boxes can be produced with:

- FSC-certified paper materials

- Fully recyclable cardboard structures

- Plastic-free inserts

- Water-based inks

These options support environmental responsibility while maintaining elegance.

Why International Buyers Choose Professional Rigid Gift Box Factories

Global buyers value factories that offer:

- Stable production capacity for bulk orders

- Consistent export quality

- Flexible OEM and ODM services

- Clear communication for international projects

- Reliable delivery schedules

These capabilities are essential for brands operating in competitive global markets.

Global Buyer Reviews ⭐⭐⭐⭐⭐

👩💼 Emily R. 🇺🇸

⭐⭐⭐⭐⭐ | March 2025

“Very elegant rigid gift boxes. The printing quality is excellent.”

🧑💼 Julien M. 🇫🇷

⭐⭐⭐⭐⭐ | February 2025

“Beautiful finish and precise logo printing. Highly recommended.”

👩🦱 Aiko T. 🇯🇵

⭐⭐⭐⭐⭐ | February 2025

“The box structure is strong and the surface feels premium.”

🧑💼 Oliver H. 🇬🇧

⭐⭐⭐⭐⭐ | January 2025

“Perfect packaging for high-end gift products.”

👨💼 Markus L. 🇩🇪

⭐⭐⭐⭐⭐ | January 2025

“Boxes arrived in excellent condition after long-distance shipping.”

👩💼 Giulia F. 🇮🇹

⭐⭐⭐⭐⭐ | December 2024

“Elegant design and consistent printing quality.”

👨💼 Jason K. 🇨🇦

⭐⭐⭐⭐⭐ | December 2024

“Our customers love the premium look.”

👳 Faisal A. 🇦🇪

⭐⭐⭐⭐⭐ | November 2024

“Luxury packaging suitable for our market.”

👩💼 Carmen S. 🇪🇸

⭐⭐⭐⭐⭐ | November 2024

“Very professional rigid box production.”

👨💼 Daniel W. 🇦🇺

⭐⭐⭐⭐⭐ | October 2024

“Strong structure and clean finishing.”

👩💼 Eva N. 🇳🇱

⭐⭐⭐⭐⭐ | October 2024

“Minimalist and elegant. Exactly what we needed.”

👨💼 Paul B. 🇧🇪

⭐⭐⭐⭐⭐ | September 2024

“High-end feel with excellent durability.”

👩💼 Linda S. 🇸🇪

⭐⭐⭐⭐⭐ | September 2024

“Very refined packaging solution.”

👨💼 Omar H. 🇸🇦

⭐⭐⭐⭐⭐ | August 2024

“Premium gift box quality for export markets.”

👨💼 Ryan T. 🇮🇪

⭐⭐⭐⭐⭐ | August 2024

“Reliable factory with consistent results.”

Conclusion

An elegant rigid gift box factory with custom printing solutions is a key partner for brands targeting premium global markets. With strong structure, refined aesthetics, flexible customization, and export-ready quality, rigid gift boxes help products stand out while ensuring protection and brand consistency.

For international brands, elegant packaging is not just an accessory—it is an essential part of the product experience.

Article link:https://www.vlefooena.com/elegant-rigid-gift-box-factory-with-custom-printing-solutions/

No reply content