From Thread to Tranquility: The Journey of Crafting Curtains That Elevate Everyday Life

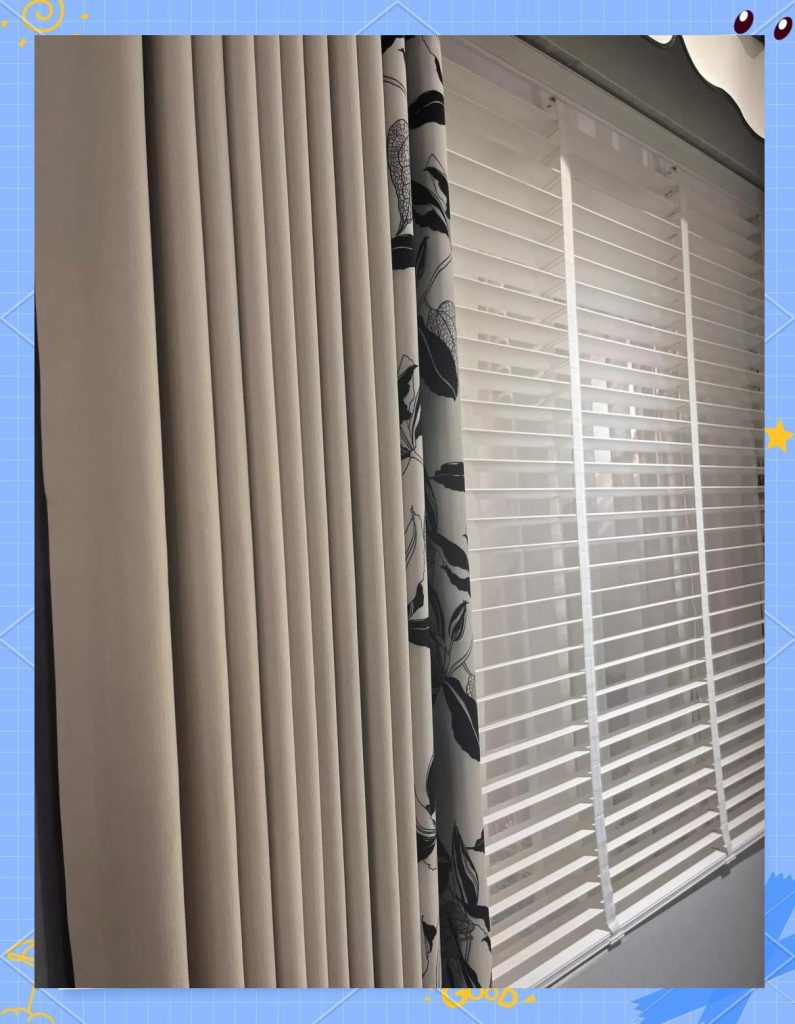

In a world where spaces shape how we feel, our factory exists to turn windows into portals of comfort, light, and intention. Here, we don’t just manufacture curtains—we engineer experiences. Every panel we create is a testament to the belief that window treatments should do more than cover glass; they should harmonize with your space, adapt to your needs, and linger in your memory long after the sun sets.

The Blueprint of Beauty: Designing for Your Story

Every curtain starts with a question: What does your space need to feel like? A family in a sunlit California bungalow might crave light-filtering linen to soften morning rays without sacrificing privacy. A boutique hotel in a historic district could seek rich velvet drapes to amplify grandeur while muffling street noise. A modern office might require glare-resistant fabrics to keep screens clear and focus sharp.

Our design team thrives on these puzzles. We collaborate directly with clients—homeowners, designers, architects—to translate visions into technical blueprints. Sketches evolve into 3D renderings, where clients “test” colors, folds, and lengths in their virtual room. “It’s not about pushing inventory,” says Elena, our lead designer. “It’s about solving for their lifestyle. Do they have kids? Pets? A love for hosting? Those details shape every stitch.”

Fabric as a Promise: Choosing What Lasts—and Loves You Back

Curtains wear many hats: they insulate, decorate, protect, and inspire. That’s why our material selection is equal parts science and soul.

-

Performance Matters: For a nursery client worried about dust mites, we chose a tightly woven cotton with a built-in anti-microbial finish. For a coastal home battling humidity, we opted for quick-dry polyester that resists mold.

-

Sustainability as Standard: Over 75% of our fabrics now carry eco-certifications—GOTS organic cotton grown without pesticides, recycled polyester from post-consumer bottles, and Tencel™ lyocell from sustainably managed forests. We even partner with dye houses that recycle 98% of water, ensuring our processes leave minimal footprints.

-

Touch and Feel: We reject “pretty but prickly.” Every fabric is tested for softness, drape, and longevity. A velvet that pills after 10 washes? Rejected. A linen that wrinkles unattractively? We refine the weave until it drapes like liquid.

“Our clients don’t just want curtains that look good today,” explains Mei, our fabric curator. “They want curtains that feel good for years—in their home, in their family, in the world.”

The Art of Assembly: Where Precision Meets Passion

Walk our factory floor, and you’ll witness a symphony of skill. Automated cutters slice fabric with millimeter accuracy, ensuring every panel matches the blueprint—no crooked hems, no uneven panels. But the soul of the process lives in our artisans:

-

Hemming by Hand: Sewing machines handle bulk stitching, but master tailor Raj hand-finishes each hem. “Machines follow numbers,” he says. “I adjust stitch length for silk, tension for wool—so the hem hangs light, never bulky.”

-

Lining as Craft: Blackout layers aren’t just glued; they’re heat-fused with precision. This prevents stiffness, ensuring curtains flow smoothly even when fully closed.

-

Grommets with Care: Metal rings are aligned with laser guides, then hand-tightened. “A loose grommet snags,” says Priya, our finisher. “We check twice—once for position, once for smoothness.”

These touches aren’t “extras”—they’re what transform a curtain from a product into a piece you notice, then forget, because it fits so seamlessly into your life.

Quality That Transcends Time: The 20-Year Test

In an era of fast fashion, we measure success by longevity. Every curtain undergoes a grueling 20-point inspection:

-

Wash Testing: Fabric is laundered 15 times to simulate years of use, checking for shrinkage, fading, or pilling.

-

Stress Tests: Seams are tugged with industrial tools to ensure they won’t unravel.

-

Light Exposure: Panels spend 100 hours under UV lamps to guarantee colors stay vibrant—no bleeding, no dulling.

“Our goal is for your curtains to outlive trends,” says Carlos, our QC director. “When you hang these, you shouldn’t have to think about them—for decades.”

More Than a Factory: A Partner in Your Space

What makes us different? The people. From interns learning to thread needles beside retirees who’ve sewn here since 1985, to office staff who personally call clients to confirm delivery dates, we treat every order as if it’s for our own home. During last winter’s storms, we prioritized waterproof curtains for families in flood zones—working nights and weekends because “needs don’t wait for business hours.”

The Final Fold: Curtains That Feel Like Home

So the next time you draw open a curtain and light spills across your floor, remember—behind that simple motion lies a story. A story of hands that cared, eyes that checked, and a factory that refused to cut corners.

Here, we don’t just make curtains. We craft tranquility. We weave moments. We build trust—one thread, one panel, one happy home at a time.

Because a well-made curtain isn’t just a window treatment. It’s a promise that your space will feel like you—every day, for years to come.

Article link:https://www.vlefooena.com/from-thread-to-tranquility-the-journey-of-crafting-curtains-that-elevate-everyday-life

No reply content