Leather is made from animal skin by a series of physical and chemical processes. The process of making leather out of rawhide (raw skin from an animal) is called tanning.

Tanning is a complicated process with a long cycle. Generally, the tanning process is divided into three stages: preparation stage, tanning stage and finishing stage.

The main processes include soaking, meat removal, hair removal, ash leaching, degreasing, softening and acid leaching. The main function of the preparation stage is to remove some components of raw skin that are not conducive to tanning, such as coat, blood stain, fat and some soluble proteins. And the collagen fibers of the raw skin were loosened and softened to facilitate the processing of the later process.

(2) tanning stage

The main processes include pre-tanning, tanning and retanning. This is the crucial stage of tanning,

Through tanning, collagen fibers undergo structural changes from rawhide (raw hide) to durable, functional leather.

(3) Finishing stage

The main processes include leveling, neutralizing, dyeing, fatten, drying, flattening, leather grinding, finishing and embossing. In this stage, the leather after tanning is finished, so as to obtain different color varieties of leather. For example, leather with different colors and patterns can be obtained by dyeing, finishing and embossing, and leather with different thicknesses and different degrees of softness can be obtained by sharpening, fatening and filling.

1. What kinds of leather are usually divided into?

(1) Classification by use

According to the use of leather can be divided into: shoe upper leather, clothing leather, shoe leather, sofa leather and glove leather.

(2) Classification by processing method

According to the processing method, leather can be divided into front leather, split leather, suede, frosted leather and film shifting leather.

(3) According to the species of animal skin classification

1) Domestic animal skin: cattle skin, buffalo skin, yak skin, horse skin, donkey skin, pig skin, goat skin and sheep skin, etc.

2) Wild animal skin: antelope skin, suede, deer skin, wild boar skin and kangaroo skin, etc.

3) Fish snakeskin: crocodile skin, lizard skin, snake skin, python skin and shark skin, etc.

4) Bird skin: ostrich skin, etc.

2. How is tearing force defined? What is the impact of this index on leather products?

Tearing force: the rectangular leather sample of the specified shape (with holes in the middle) is placed on the test hooks of the upper and lower jigs of the tension testing machine. The maximum load value reached during the operation of the tension testing machine is the tearing force of the sample. Tearing force can also be interpreted as the ability of leather to resist the tearing action of external forces.

Tear force is an important index to measure the strength of leather, especially for leather clothing. Leather clothing must be supported by a certain tearing force index to ensure normal wear. Clothing leather requirements: sheep leather ≥1lN, cattle leather ≥13N, other small animal leather ≥9N.

Three, how to define the bending fastness of the coating?

The leather sample twists and turns in the specified testing instrument until the surface or body produces discoloration, fuilling, crack, shell, pulp and other phenomena so far. The zigzagging times indicate the zigzagging resistance of the leather.

The bending fastness of coating is an index to measure the bending resistance of leather and finish layer. When people walk, the vamp material will be bent for countless times, which requires the vamp leather to have a certain fastness to folding, so as to ensure that the shoe vamp material in a certain period of wear, no cracks, no damage. Therefore, the bending fastness of coating is an important index of the vamp leather.

Four, what is the color fastness to rubbing?

Rubbing color fastness is the degree to which the leather surface color and coating change or transfer under the action of friction. During the color fastness test, the white interlining or white wool adhesive specified in the standard is used. Under a certain pressure (500g, 1000g test head mass), reciprocating friction is carried out on the leather surface (reciprocating friction with dry white interlining or white wool adhesive is used as dry rub, and reciprocating friction with wet white interlining or white wool adhesive is used as wet rub). The change of leather color and the stain of white interlining or white wool were evaluated with standard gray sample card.

Rubbing color fastness is an index to measure whether leather is decolorized. It is an important inspection item of leather clothing and other leather products. Leather products with unqualified color fastness (decolorization, serious fading) will directly affect the normal wear.

Five, what is the adhesion fastness of the coating? What is the difference between color fastness and rubbing?

Leather is usually finished in the production process for excellent appearance and colorful colors. The adhesion fastness of the coating is the adhesion between the leather finishing layer and the leather (or between the finish layer and the finish layer), which is two different concepts from the color fastness of friction. The rubbing color fastness is an index to measure whether the leather is decolorized, and the adhesion fastness of the coating is an index to measure the adhesion between the leather coating and the leather. The adhesion fastness of the coating is high, indicating that the coating layer and the leather combination is good fastness, that is to say, the coating is strong; The poor adhesion fastness of the coating will cause the coating layer to fall off when wearing leather products, which has a serious impact on the appearance of the product.

Six, what is full grain leather (top layer leather)?

Full-grain leather refers to the leather that retains and uses the grain layer of animal skin, also called front leather, head leather. The raw materials used in full-grain leather require less injury, and the processing requirements are high, so full-grain leather is a kind of high-grade leather compared with two-layer leather and film leather. Because the grain layer of leather remains intact on the leather, its physical strength is relatively high. The finishing layer of full-grain leather is generally thin, which not only retains the soft elasticity of the leather, but also maintains good air permeability and moisture permeability. Therefore, leather products made of full-grain leather are very comfortable to use. As the grain pattern remains intact, the natural pores and texture are clearly visible, so it is very beautiful.

Seven, what is modified face leather?

Finishing leather is a type of leather in which the grain surface is partially milled to reduce the effect of grain defects and then refinished. In general, the raw materials with more injuries or other defects are used to make modified face leather. Compared with full-grain leather, the modified leather has a thicker finishing layer. So its air permeability, physical and mechanical properties, flexural resistance and aging resistance are reduced.

Eight, what is double leather?

In the process of leather processing, in order to make full use of raw material skin, generally thicker animal skin (such as cowhide, pig skin) is dissected into several layers by the machine, the leather with grain layer is the first layer of leather, the first layer of leather is called two layer of leather, three layer of leather and so on. Two – layer leather generally made suede, film – shifting leather, etc. Compared with the first layer leather, the strength of the two layer leather is lower, and the two layer film shifting leather is permeability and permeability

Water vapor decreased significantly, so double leather is relatively low grade leather.

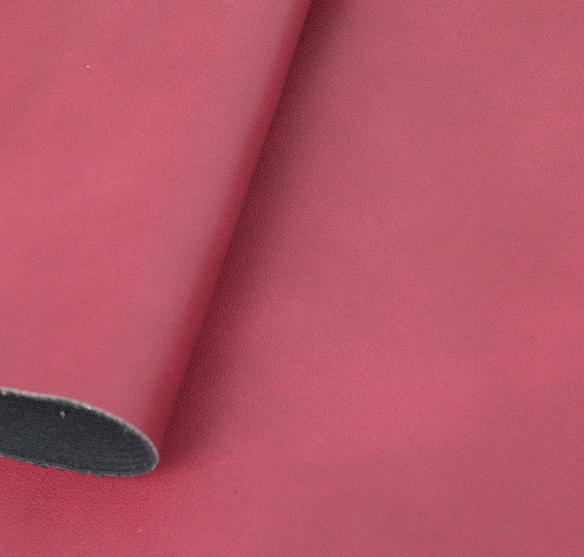

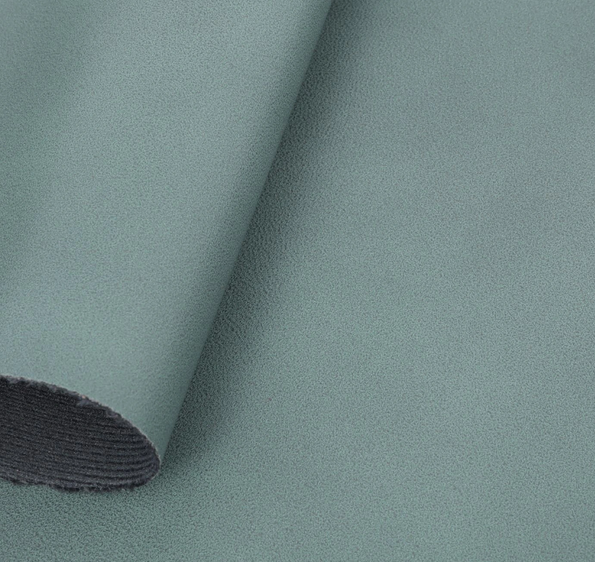

Nine, What is suede?

Suede refers to the surface of the velvet leather, generally with pig skin, cowhide, sheepskin production suede. Suede that is ground on the grain (front) of leather is called regular suede, suede that is ground on the flesh (back) of leather is called reverse suede, suede that is made of two layers of skin by grinding is called two layers suede. Suede has no finishing layer, so it has very good air permeability, but water resistance, dust resistance and maintenance are relatively reduced. Suede made of leather products, wear comfortable, health performance is better. But suede dirty is not easy to clean and maintain, cleaning should also pay attention to fade and fading problems.

10. What is the difference between the properties of top layer leather, trim leather and double layer leather?

There are differences in physical properties between top layer leather, trim leather and double layer leather. Under the same thickness condition, the physical strength of top layer leather is higher than that of double layer leather. For example, in the standard of garment leather, the tearing force index of cow leather is ≥13N, and the tearing force index of cutiform leather is ≥9N. In the leather standard for the upper, the fastness index of the coating is required: the front leather is 20000 times without crack, and the trimmed leather is 5000 times without crack. It can be seen that the physical property index of the top layer leather ~ is higher than that of the trim leather and the double layer leather.

11. What is film shifting leather?

The prefabricated finishing film adhered to the leather surface is called moving film leather. Film leather according to the production process is divided into dry film leather and wet film leather.

(1) dry transfer film leather

A polyurethane (Pu) finishing material is applied to a freestanding paper to make a film, which is then transferred to the surface of the leather for processing.

(2) wet transfer film leather

The solvent-based polyurethane (Pu) was coated on the leather surface by roller coating method, so that the polyurethane resin formed a continuous porous film on the leather surface, and then the polyurethane (Pu) film made on the off-shape paper was transferred to the leather surface or the leather was processed by spraying and embossed technology.

In the production, it is generally used to make film shifting leather, which not only reduces the cost but also improves the utilization rate of raw material leather. Film leather can be made of various colors, various patterns. Film moving leather is widely used in shoes, bags, belts and other leather products.

What is recycled leather?

A large amount of solid waste is generated in the traditional process of leather making, such as the skin pieces produced by the trimming of wet blue skin, the debris generated during the sharpening and other kinds of waste, and the leather scraps and the edge scraps produced during the processing and production of leather products. Often, the waste is shipped to landfills, which increases the cost of leather production and endangers the environment. Recycled leather is a product made of the waste material of leather, which is crushed into leather fiber, mixed with adhesive or resin and other additives, pressed into shape, and then processed by surface coating. Generally speaking, the longer the skin fibers in regenerated leather are, the more stable the properties are. In raw materials

The larger the proportion of long fiber, the better the physical properties of the product. If the raw material contains too much crumb, the strength and overall performance of the product will be affected, its physical properties and durability will be compromised. Because recycled leather is made of leather waste products, the cost is relatively low, but its fastness, water resistance, durability and health properties are not as good as natural leather, recycled leather is mainly used as an auxiliary material for leather products, can also be used to make back bags, belts and so on.

Thirteen, which animal fur can make fur?

There are many kinds of wild animals in our country. There are more than 80 kinds of animals whose fur can be made into fur. Our country fur animal breeding industry started in 1956, and the artificial fur animal included: mink, Arctic fox, silver black fox, nutria, raccoon, Rex rabbit, Muskrat (raccoon), erkat, fur rat, beaver and so on more than 10 kinds of animals. Domestic animal fur generally includes a variety of sheep skin, cashmere skin, dog fur, rabbit skin and domestic cat skin. Fur classification methods are also many, some according to domestic animal fur, beast fur and sea animal fur classification; Some are classified by lanugo, small hair and large hair. Some are classified by coarse fur, shaggy fur, small fur and large fur.

14. What are the kinds of Chinese sheep fur?

There are many kinds of sheep fur in our country, which can be divided into fine wool, semi-fine wool, coarse wool and lamb according to production performance. The fine wool sheep are represented by Xinjiang fine wool sheep, Northeast fine wool sheep and Inner Mongolia fine wool sheep, the semi-fine wool sheep is represented by Han sheep, the coarse wool sheep is represented by Mongolian sheep and Kazak sheep, and the lamb skin sheep is represented by Tan sheep and Hu sheep. According to the use of sheep fur and the characteristics of wool type, sheep skin is generally divided into three categories: native sheep skin, improved sheep skin and hybrid sheep skin.

(1) native sheep skin

Native sheep fur with long wool thick, loose, hair tuft flower bend clear, leather plate flexible characteristics, can be made of all kinds of fur fur clothes, gloves and shoes.

(2) Improving sheep skin

The wool of the improved sheep skin is fine and even, with a small bend. Made of fur, can be cut fur, dyed a variety of colors, leather clothing, leather cap, leather collar, leather plate and so on.

(3) hybrid sheep skin

Hybrid sheepskin includes tan sheepskin, lake sheepskin and Sanbei sheepskin, but its quality is different and its use is the same as this kind of sheepskin. The pelt of young sheep is called lamb pelt, divided into this kind of lamb and improved lamb two kinds. They are divided into small, medium and large wool lambs according to the length of their hair. Short hair, obvious pattern is suitable for making fur coat and fur hat. Longer hair, uneven thickness can be made of coat, leather plate and collar.

15. What is the forbidden azo dye in leather? What is the harm to human body?

Azo dyes are dyes that contain azo groups in their molecular structure. Prohibited azo dyes are dyes that can crack one or more of the amines listed in the table below. After testing, its content of more than 30mg/kg, is considered to be leather and fur in the processing process using banned azo dyes, harmful aromatic amines can cause human cancer. Therefore, the use of split-interpretation in leather and leather products should be prohibited

16. Why should formaldehyde and hexavalent chromium be restricted in leather and fur products? What harm does formaldehyde and hexavalent chromium have to human body?

In the process of leather and fur production, formaldehyde or other aldehydes are sometimes used for tanning, or as a fixing agent. Most formaldehyde is produced in tanning and retanning. The formaldehyde used for fixing after finishing is also the direct source of formaldehyde in leather. As leather and fur are the main raw materials of various leather products, formaldehyde will be brought into leather products. Formaldehyde is a colorless gas with a strong pungent odor. It has a strong stimulating effect on human senses, mildly irritating to human eyes, skin and mucous membranes, and seriously causing respiratory tract inflammation and dermatitis. In the European Union, formaldehyde is listed as a carcinogenic substance. Some developed countries have limits on formaldehyde content in leather. For example, German regulations: formaldehyde content of footwear <150mg>

Formaldehyde content of furniture leather <150mg>

Hexavalent chromium ions in leather have considerable toxicity, the toxicity of hexavalent chromium ions is more than 100 times higher than that of trivalent chromium ions. If leather products are in direct contact with the human body, free chromium ions are easy to enter everyone’s body with sweat, resulting in skin damage, various diseases and even cancer. Therefore, some developed countries have made clear regulations and limits on the free hexavalent chromium content in leather products, and the maximum limit is generally in

Less than 5mg/kg. In fact, the chromium ions in the chrome tanning agent used in the leather production process are trivalent chromium ions, but the hexavalent chromium ions can often be detected in leather. The reasons for this situation are very complicated, which may be due to the oxidation of the trivalent chromium ions into hexavalent chromium ions by the fat-raising agent used in the leather or the high pH value conditions in the leather processing and the heating, light, humidity and other reasons. In any case, it is necessary to control the hexavalent chromium in leather.

17. How is the smell of leather products formed?

Leather is made from animal skin through complex physical and chemical processes. In the process of tanning, will add a variety of acid and alkali treatment leather, add a variety of fat agent for fat, and fill with a variety of fillers, and finally finish with finishing agent. Because the raw leather skin itself has a smell, coupled with a variety of leather chemical materials in the process of leather, the formation of leather unique smell. Because of the different kinds of raw materials, as well as the different skin materials used, the smell of leather is light and heavy. For example, fish oil added to the leather will be more or less fishy smell; With solvent-based finishing agent to finish the leather will have some solvent odor; There will be the smell of adhesives in leather and fur products, and even the smell of formaldehyde and benzene. Obviously, some poisonous and harmful gases are harmful to human health. In the standard QB/ T2725-2005 “Determination of Leather Odor”, the grade of odor is divided into five levels:

Grade l: No noticeable odor;

Level 2: slightly smelly, but not noticeable;

Level 3: obvious odor, but not offensive;

Level 4: Strong, unpleasant odor;

Level 5: Very strong unpleasant odor.

Leather and its products because of its particularity, more or less will have some smell, but in the car cushion leather, sofa leather and other leather, the smell of leather should be controlled.

Article link:https://www.vlefooena.com/manufacturer/1460/

No reply content