I. Overview of greenhouse:

1. Choice of greenhouse type:

· Combined with the local climate characteristics of Shandong, taking into account the applicability requirements and overall aesthetics of the greenhouse, our company suggests the design of the circular arch hot-dip galvanized light steel structure greenhouse;

· The greenhouse structure is simple, bright, transparent, beautiful appearance, durable, strong environmental control ability; Good light transmittance, good ventilation effect; It is a kind of greenhouse with good comprehensive performance at present.

2. Basic configuration of greenhouse

In order to better use the greenhouse for users, reduce the overall operating cost, improve the environmental regulation ability and automatic control level, so that the greenhouse to achieve the best configuration, the basic configuration of the greenhouse is as follows: forced ventilation cooling system (fan, wet curtain), internal shading system, external shading system, power distribution, etc.

3, the greenhouse size:

The greenhouse has a span of 8m, a space of 4m, and a shoulder height of 4m. The top and surrounding areas are covered with 15 wire po films. The length of the greenhouse is 184, with 23 spans; Width 68m, a total of 17 rooms. The total area of greenhouse is 12512 square meters; The top height of the greenhouse is 5.7 meters. Water distribution and drainage facilities are provided around the greenhouse.

4. Greenhouse performance indicators:

1) Wind load: 0.35KN/m2

2) Snow load: 0.30KN /m2

3) Greenhouse drainage: 140mm/h

4) Power parameters: 220V/380V,50Hz,PH1/PH3

5, greenhouse roof drainage

The greenhouse is equipped with 2.5‰ rain trough slope drainage. Roof drainage adopts the combination of indoor and outdoor drainage, PVC drain pipe

Direct to the ground drain.

Two, greenhouse main body

1. Greenhouse structure:

The greenhouse adopts the main frame of circular arch roof multi-row water trough. The selected hot-dip galvanized steel pipe, rectangular steel pipe, steel plate and so on are produced by domestic large steel mills. The roof drainage tank is made of hot-dip galvanized steel plate produced by Bensteel Group. The main light steel structure is made of hot-dip galvanized steel, or hot-dip galvanized after processing.

The main structural materials are as follows:

1) The four corners and the middle column are hot-dip galvanized column 50*100*3.0mm,

2) The arch rod adopts φ32*2.0mm national standard hot-dip galvanized steel pipe with arch spacing of one meter;

3) The drainage tank adopts B=2.0mm hot-dip galvanized steel plate;

4) The beam and the surrounding beam are made of 50*50*2 galvanized rectangular hot-dip galvanized steel pipe;

5) 50*50*2 galvanized rectangular steel pipe is used for the outer sunshade longitudinal beam;

6) The structural connectors are galvanized with B=3-6mm steel plate after processing;

7) The greenhouse structural parts are connected with hot-dip galvanized bolts and self-drilling nails.

2. Greenhouse door: (can be changed according to site conditions and Party A’s requirements)

The south side of the greenhouse is equipped with 1 set of special track sliding door. The size of the door is 2.0×2.2m.

3. Greenhouse covering materials:

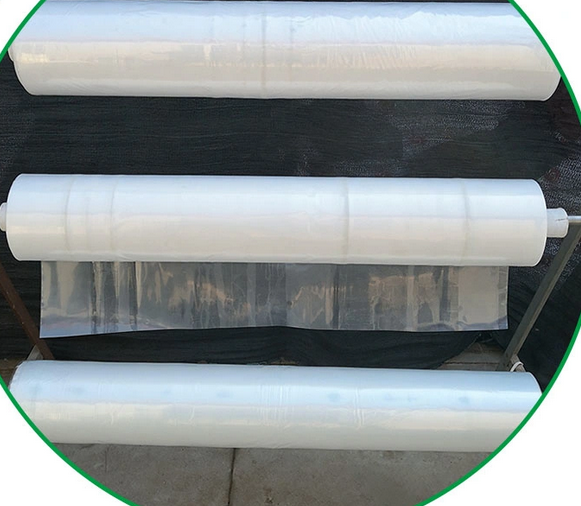

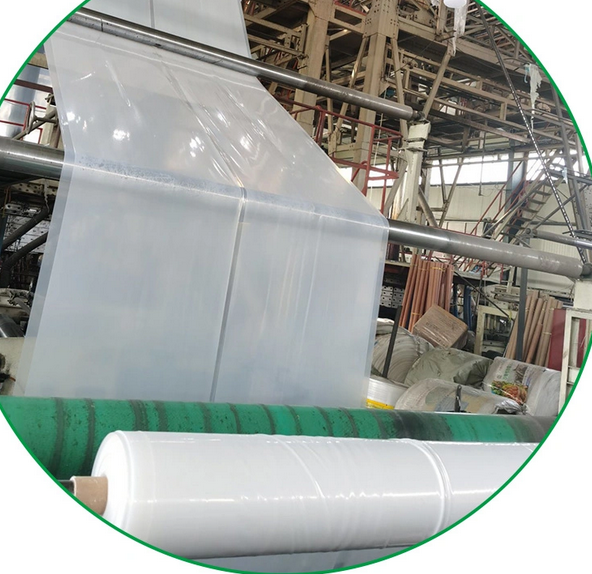

1) Greenhouse coverage

Greenhouse top and surrounding covered with 15 wire po film, greenhouse with special spring clamping groove seal; Conducive to the greenhouse lighting, light transmission and heat insulation energy saving, beautiful appearance, good visual effect.

15 wire po film Features:

I. Excellent transparency

Using advanced olefin raw materials, low fog degree, high transparency. So the transmittance of light in the morning is high, the scattering rate is low, so it will warm up quickly in the morning.

II. Super continuous fogging and dripping ability

The mist generation can be suppressed by applying the defogging drip agent, and the defogging drip period can be synchronized with the service life of agricultural film.

III. Enhanced thermal insulation performance

Special high-tech organic insulation agent is used inside the film, so that most of the infrared radiation from the shed is reflected back. Effectively control the heat loss. It ensures the growing temperature of crops at night and shorens the maturity period. It can effectively prevent freezing damage to crops caused by sudden drop of temperature at night.

IV. Long service life

Adopt high-tech antioxidant and light stabilizer, greatly extend the service life of agricultural film, normal use can reach more than 5 years.

Three, external shading system

1. Sunshade net

Choose national standard warranty five years outside the sun curtain

● Shading rate of 70%, energy saving rate of 50%

● Life: The manufacturer provides a 5-year warranty period, the actual service life is more than 8 years

2. Supporting curtain line

Double curtain line selection of national standard polyester external curtain line

● Color: black ● Diameter: 2.0×2.5㎜ ● Tensile strength: 250㎏/f

● The quality guarantee is 5 years, the service life is more than 8 years

3. Transmission mechanism

The motor drives the transmission shaft through the transmission mechanism, the transmission shaft drives the driving rod to move parallel on the curtain wire through the connecting piece, and the driving rod pulls one end of the curtain to expand slowly. After all the expansion, the travel limiter switch is triggered, the motor stops, and the travel operation ends. The control box is equipped with manual control. If you need to stop midway, you can press the stop button to stop the operation. Also can realize computer automatic control

1) Motor parameters:

● Power supply: 380V, 50HZ ● Motor power: 0.375KW

● Speed reduction ratio: 1:700 ● Output speed: 2 rpm

2) Rack pair technical parameters:

● Module: 4 ● Material: Q235 galvanized anticorrosion ● Length: 4.0m long straight rack ● Speed ratio: 1:1

4. Design conditions

In summer, when the indoor light intensity exceeds the light saturation point of crop photosynthesis, the excess light can not be reached

When the greenhouse is excluded, it will burn the plant leaves or be converted into heat energy to raise the indoor temperature, when this temperature rise exceeds that of the crop

Long suitable temperature range, too high temperature will affect the normal growth and development of crops, and even lead to serious

Crop fertility disorders, until death. Closing the shade screen will allow the light entering the greenhouse to first encounter the shade screen

The upper part, regulated according to the shading rate of the shade curtain, is either directly discharged from the greenhouse by the shade curtain reflection, or converted to the length

The wave radiation increases the air temperature in the upper part of the awning curtain and is discharged through the roof ventilation window.

Thus it can be seen that the use of shading curtain in summer has the dual role of shading and cooling in the greenhouse.

5. Working principle of the system

The motor drives the drive shaft, and the gear/rack on the drive shaft turns the circular motion into a straight motion. Connected with the rack

The connected push and pull rod drives the driving rod to move equally on the curtain wire through the cross connection, and the driving rod pulls one end of the curtain to unfold slowly.

Close, fully open and close the limiter switch respectively after closing, motor stop, end of operation.

6. Composition of external shading system

· External sunshade bracket: The top of the greenhouse shall be installed with external sunshade skeleton, and the lattice frame and 50×50 and 50×50 hot-dip galvanized square shall be selected

Pipe processing production. The grid structure is composed of galvanized square pipes and connectors. The support part has reliable strength and beautiful appearance

View, strong load bearing capacity, long service life.

· Control box: The control box is equipped with two sets of contact devices for shade curtain expansion and closing, which can be opened and stopped manually

Through the travel switch, automatic parking is realized. Control box can be equipped with temperature control, time control, light control equipment, and automatic control system

Unified connection, the realization of computer intelligent control.

· Driving motor: Special driving motor, equipped with travel limit device, automatic stop, accurate limit, also equipped with

The thermal protection device provides safety guarantee for user operation.

· Transmission part: the gear and rack transmission mechanism is adopted, and the shaft outputs power through the transmission connected with the reduction motor.

The middle part of the drive shaft is connected with the motor, and the rest of the rack is connected; The driving rod and pushing curtain are made of hot-dip galvanized components.

High structural strength, stable and reliable operation.

Curtain line: double curtain line with a diameter of 2 mm high quality polyester supporting curtain line, rust, high strength.

Curtain: The outer sunshade curtain is made of domestic high quality black knitted curtain, shading rate of 70%. The manufacturer provides a shelf life of 5 years.

Service life more than 8 years.

Article link:https://www.vlefooena.com/manufacturer/1469/

No reply content