Curtains have evolved into multifunctional design elements that transcend mere aesthetics—they are now pivotal in shaping sustainability, functionality, and user experience. From hotel curtains that enhance guest well-being to bedroom curtains tailored for personalized comfort, the integration of custom curtain manufacturing and OEM solutions is driving unprecedented advancements. This article unpacks the latest trends, challenges, and opportunities reshaping the industry.

—

1. Hotel Curtains: Sustainability as a Core Pillar

The hospitality sector faces mounting pressure to adopt eco-conscious practices. Modern hotel curtains now prioritize:

– Circular Materials: Recycled ocean plastics, upcycled textile waste, and OEKO-TEX® certified fabrics to reduce environmental footprints.

– Energy Efficiency: Thermochromic linens that reflect sunlight in summer or retain heat in winter, reducing HVAC usage by up to 20%.

– Hygiene-Forward Design: Antimicrobial coatings and easy-clean fabrics compliant with health standards (e.g., ISO 20743).

*Trend Alert*: 65% of travelers now prefer hotels with sustainable curtain solutions, per a 2023 industry survey.

—

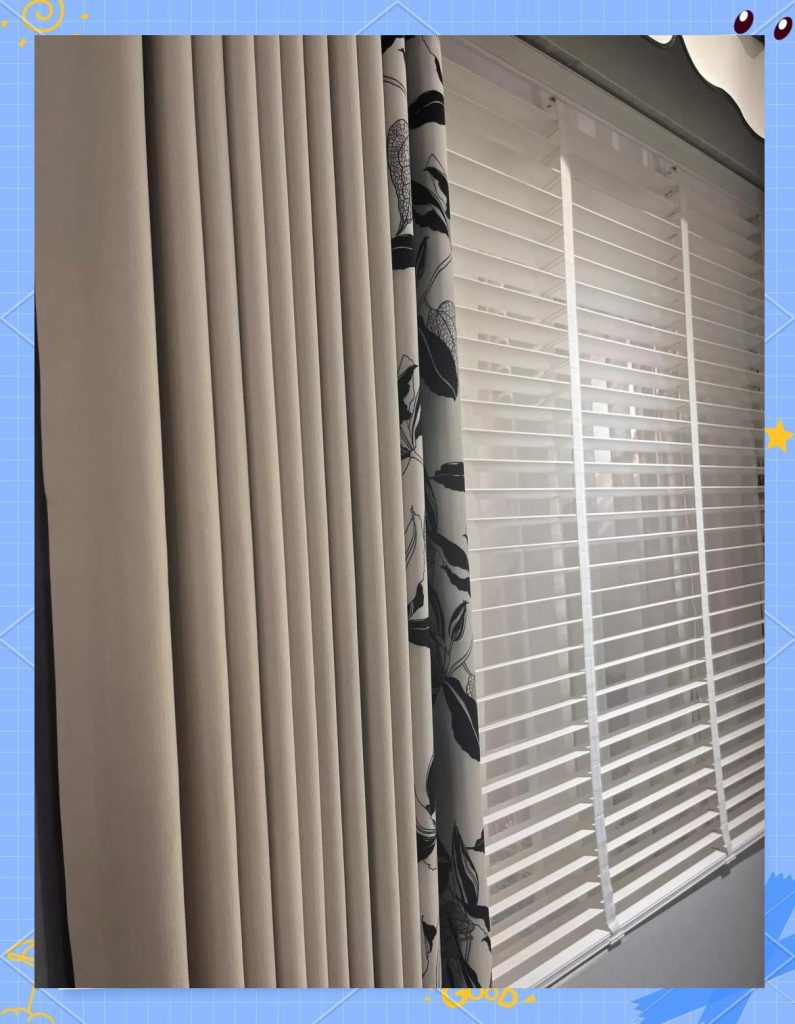

2. Bedroom Curtains: Merging Wellness with Technology

Modern bedrooms demand curtains that support physical and mental wellness through:

– Circadian Lighting Compatibility: Blackout curtains with dimmable layers to align with natural sleep cycles.

– Air-Purifying Fabrics: Textiles infused with photocatalytic nanoparticles to neutralize indoor pollutants.

– Smart Automation: Voice-controlled motorization synced with smart thermostats for holistic climate control.

Collaboration with a custom curtain factory enables bespoke solutions like magnetic privacy panels or 3D-embroidered artwork.

—

3. Custom Curtain Factories: The Backbone of Scalable Innovation

Specialized manufacturers empower businesses with:

– Agile Design Processes: Rapid iteration from concept sketches to prototypes using AI-assisted pattern generation.

– Cost-Effective Scalability: Bulk production with modular workflows, reducing lead times by 30% for hotel chains.

– Sustainability Audits: End-to-end supply chain transparency, from ethical fiber sourcing to zero-waste dyeing techniques.

For brands, OEM manufacturing eliminates upfront infrastructure costs, enabling lean operations focused on branding and distribution.

—

4. OEM Manufacturing: Balancing Customization and Speed

OEM partnerships are redefining how businesses approach window treatments:

– Digital Twin Technology: Virtual replicas of fabrics and constructions to predict performance before production.

– On-Demand Production: Just-in-time manufacturing models to minimize overstock and waste.

– Global Compliance Networks: Facilities certified in ISO 9001, GOTS, and Cradle to Cradle® for seamless international shipping.

*Case Study*: A European retailer reduced time-to-market by 60% by partnering with an OEM factory for seasonal curtain collections.

—

5. The Future: AI, IoT, and Beyond

Innovations set to dominate the next decade:

1. AI-Driven Personalization: Algorithms generating curtain designs based on user lifestyle data (e.g., light exposure preferences).

2. IoT-Enabled Curtains: Self-adjusting systems that sync with weather forecasts or occupancy sensors.

3. Biofabricated Textiles: Lab-grown fabrics using algae or mushroom mycelium for zero-environmental-impact solutions.

—

Conclusion

From hotel curtains that prioritize guest health to bedroom curtains enhancing daily well-being, custom curtain factories and OEM manufacturing are unlocking unprecedented possibilities. As sustainability and smart technology converge, these innovations position window treatments as strategic assets in creating memorable, future-ready spaces.

Article link:https://www.vlefooena.com/manufacturer/3387/

No reply content