The global demand for high-quality curtains has propelled Chinese curtain processing factories into a pivotal role within the textile and home décor industries. Renowned for their precision, scalability, and cost-effectiveness, these factories combine traditional craftsmanship with cutting-edge technology to deliver customized solutions for residential, commercial, and hospitality markets worldwide. This article explores the strengths, processes, and innovations driving China’s curtain manufacturing sector.

—

1. The landscape of Chinese Curtain Processing Factories

China’s curtain manufacturing industry thrives on a robust foundation of advanced textile production capabilities. From sourcing premium fabrics like velvet, linen, and blackout materials to integrating smart home-compatible hardware, factories prioritize end-to-end solutions tailored to diverse customer needs. Key advantages include:

– Cost-efficiency: Streamlined production lines and competitive labor costs enable high-quality outputs at scalable prices.

– Technical expertise: Mastery of techniques such as pleating, layering, and fabric printing ensures durability and aesthetic appeal.

– Sustainable practices: Many factories now adopt eco-friendly dyeing methods, recycled fabrics, and energy-efficient machinery to align with global sustainability trends.

—

2. Core strengths of Chinese curtain manufacturers

Customization and design flexibility

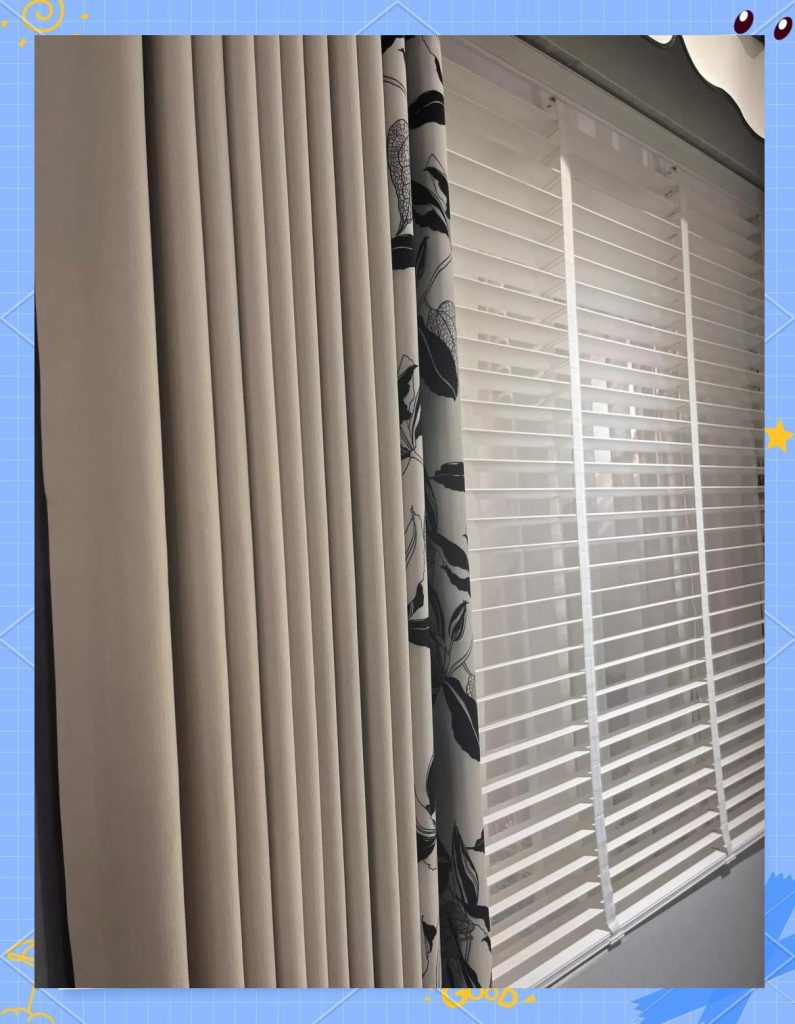

Factories employ skilled designers and digital tools to translate client visions into reality. Whether creating bespoke Roman shades, motorized drapes for large commercial spaces, or minimalist interior panels, manufacturers emphasize precision in measurements and finishing touches.

Advanced machinery and automation

Modern facilities integrate computerized cutting systems, automated stitching units, and digital printing technologies. These innovations reduce human error, accelerate production timelines, and ensure consistency across batches.

Quality assurance protocols

Rigorous inspection processes—from fabric stress testing to final product functionality checks—guarantee durability, colorfastness, and compliance with international standards (e.g., OEKO-TEX, GOTS).

—

3. The curtain production process: From concept to delivery

A typical partnership with a Chinese curtain factory involves:

1. Design consultation: Clients provide specifications, fabric choices, and functional requirements.

2. Material selection: Factories recommend durable, fade-resistant fabrics suited to climate and usage.

3. Prototyping: A sample is created for approval, ensuring alignment with design and technical standards.

4. Mass production: Automated systems execute precise stitching, pleating, and hardware integration.

5. Quality testing: Products undergo stress, lightfastness, and functionality tests.

6. Logistics: Efficient shipping networks ensure timely global delivery.

—

4. Embracing innovation for future growth

Chinese curtain factories are increasingly adopting Industry 4.0 technologies, such as IoT-enabled production monitoring and AI-driven design tools. Additionally, the rise of smart curtains—equipped with motorized controls, light-blocking sensors, or voice-activated automation—has spurred R&D investments in IoT integration.

—

5. Sustainability as a strategic priority

To meet eco-conscious consumer demands, leading factories prioritize:

– Organic and recycled fabrics: Reducing environmental footprints without compromising quality.

– Waterless dyeing: Minimizing water waste in fabric treatment processes.

– Closed-loop systems: Recycling water and fabric scraps during production.

—

Conclusion

Chinese curtain processing factories remain indispensable to the global textile market, offering unmatched expertise in blending tradition with innovation. By combining cost efficiency, technical prowess, and a commitment to sustainability, these manufacturers continue to shape the future of interior design. For businesses seeking reliable, high-quality curtain solutions, partnering with a specialized Chinese factory provides a strategic advantage in quality, customization, and scalability.

Article link:https://www.vlefooena.com/manufacturer/3578/

No reply content