Discover how China’s leading packaging box manufacturers combine cutting-edge technology, eco-friendly materials, and precision engineering to deliver high-performance packaging solutions. Optimize your brand’s sustainability and cost-efficiency with expert insights from industry leaders.

—

Introduction to China’s Packaging Manufacturing Leadership

As the world’s largest hub for precision manufacturing, China’s packaging box factories are renowned for their ability to blend innovation, sustainability, and scalability. From e-commerce logistics to luxury retail, Chinese manufacturers produce over 300 billion packaging units annually, setting global benchmarks for durability, design flexibility, and environmental responsibility. Partnering with these factories enables brands to reduce costs by up to 40% while accessing state-of-the-art technology and carbon-neutral solutions.

—

Why Global Brands Choose Chinese Packaging Factories

1. Unrivaled Production Efficiency

– Automated Workflows: AI-driven machinery and robotic assembly lines ensure consistent quality and faster turnaround times, handling orders from 100 to 1 million units seamlessly.

– Vertical Integration: End-to-end control over raw materials, printing, and logistics minimizes delays and guarantees on-time delivery.

2. Sustainable Material Innovation

– Eco-Conscious Options: Recycled cardboard, biodegradable PLA coatings, and water-resistant mushroom-based packaging reduce environmental impact.

– Certifications: Factories comply with FSC, ISO 14001, and CARB Phase 2 standards, ensuring materials meet global sustainability criteria.

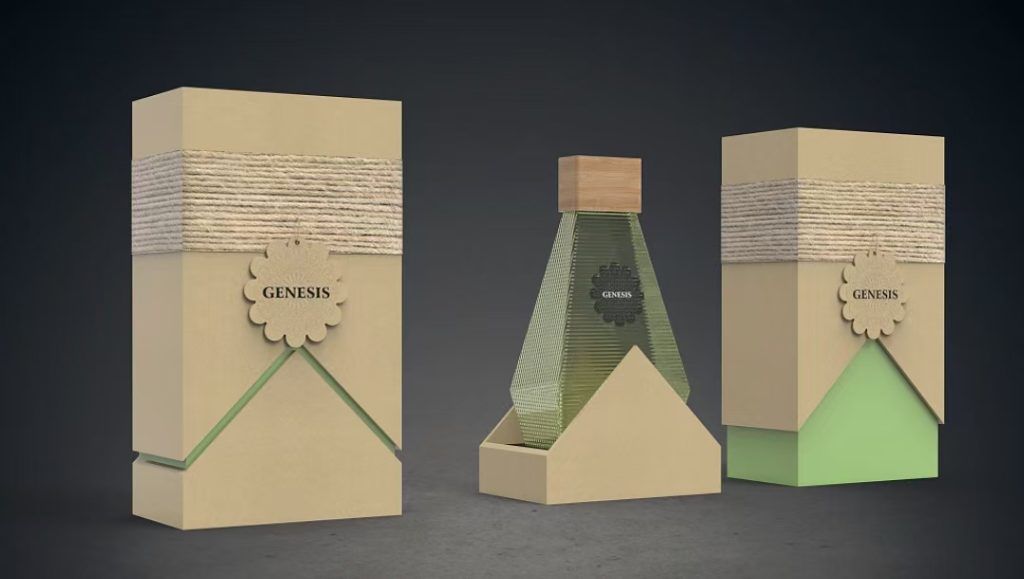

3. Custom Design & Branding Expertise

– 3D Prototyping: Digital tools enable rapid visualization of structural and aesthetic designs, accelerating approval processes.

– Functional Customization: Reinforced seams for e-commerce, anti-counterfeit features (e.g., holographic labels), and tamper-evident seals for luxury goods.

—

Core Competencies of Top Packaging Factories

1. Precision Engineering

– Laser-Cutting & CNC Routing: Achieve micron-level accuracy for intricate designs, ensuring perfect alignment in multi-layered boxes.

– Structural Optimization: Engineers use CAD software to balance weight, strength, and material efficiency, reducing shipping costs by up to 25%.

2. Sustainable Production Practices

– Zero-Waste Manufacturing: Closed-loop systems recycle scrap materials, achieving 95% material utilization rates.

– Energy Efficiency: Solar-powered facilities and AI-driven machinery cut carbon emissions by 30–50%.

3. Rigorous Quality Assurance

– Compliance Testing: Packages undergo drop tests, compression tests, and environmental simulations (e.g., humidity, temperature extremes).

– Global Certifications: FDA, ISTA, and EU compliance ensure seamless market access.

—

Industry-Specific Packaging Solutions

1. E-Commerce & Logistics

– Lightweight, foldable boxes with reinforced corners to minimize shipping damage.

– Custom inserts for fragile items, reducing returns and replacement costs.

2. Luxury Goods

– Magnetic closures, silk-screened finishes, and velvet lining for premium unboxing experiences.

– Anti-counterfeit technologies like NFC tags and unique QR codes.

3. Food & Beverage

– Aseptic packaging for extended shelf life.

– Compostable clamshell containers with moisture-resistant coatings.

—

Technological Advancements Driving Innovation

1. Smart Packaging Integration

– NFC-enabled tags for consumer engagement (e.g., unlocking AR experiences or product details).

– IoT sensors that monitor freshness and humidity during transit.

2. AI-Driven Design

– Algorithms optimize box dimensions to maximize cargo space, lowering shipping costs by up to 20%.

– Generative design tools create unique structures with minimal material usage.

3. Blockchain Traceability

– End-to-end visibility for compliance tracking, ensuring ethical sourcing and production.

—

Global Buyers’ Guide to Partnering with Chinese Factories

1. Cost Efficiency

Competitive labor costs and economies of scale enable pricing 30–50% lower than Western manufacturers, without sacrificing quality.

2. Scalability

Flexible production lines adapt to fluctuating demand, ideal for seasonal peaks or product launches.

3. Regulatory Compliance

Experienced factories handle labeling, documentation, and certifications for target markets (e.g., FDA for the U.S., CE for Europe).

4. Logistics Solutions

Integrated shipping partners offer door-to-door services, including customs clearance and door-to-door freight.

—

The Future of Packaging Manufacturing

As consumer demand for sustainability and personalization grows, Chinese factories are investing in R&D for biodegradable materials, AI-driven efficiency tools, and circular economy models. Collaborations with global brands further drive innovation in smart packaging and zero-waste systems.

—

Why Global Brands Trust Chinese Packaging Factories

1. Consistency: Standardized processes ensure uniform quality across every order.

2. Innovation: Cutting-edge techniques keep brands ahead of market trends.

3. Responsiveness: Dedicated project managers streamline communication and expedite revisions.

—

Partner with China’s Leading Packaging Box Manufacturer Today

Whether you need minimalist retail packaging, rugged shipping solutions, or luxury gift boxes, Chinese packaging factories deliver unmatched value through expertise, sustainability, and scalability. Let’s collaborate to create packaging that protects your products, elevates your brand, and resonates with global consumers.

Contact Us to discuss your vision, request a quote, or explore material options today!

Article link:https://www.vlefooena.com/manufacturer/3654/

No reply content