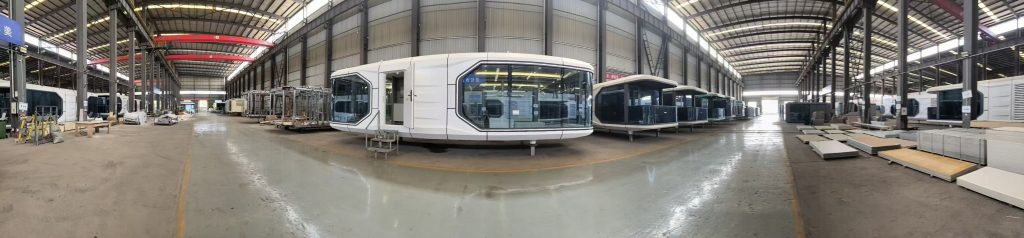

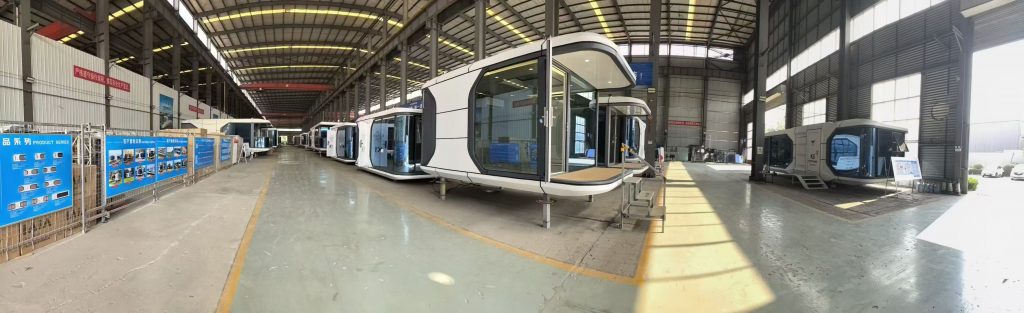

The global demand for agile, sustainable, and rapidly deployable infrastructure has catalyzed a paradigm shift in construction: the rise of modern mobile prefab structures. These factory-manufactured, transportable units are redefining how communities, businesses, and governments address spatial needs—from temporary housing in disaster zones to permanent retail hubs in remote areas. Unlike traditional buildings, which are bound by fixed locations and lengthy construction timelines, mobile prefab structures merge industrial efficiency with nomadic flexibility, offering a turnkey solution for projects spanning continents. This article explores the core attributes that make these structures indispensable for global deployment, focusing on their factory precision, mobility, versatility, and alignment with modern sustainability goals.

1. Factory-Made Excellence: Precision, Speed, and Consistency

-

Automation-Driven Precision: CNC machines cut steel beams, composite panels, and insulation materials to exact millimeter tolerances, ensuring seamless assembly. Robotic welding arms join structural frames with repeatable accuracy, reducing human error by over 90%.

-

Rigorous Quality Control: Each unit undergoes 15-stage inspections, including load-bearing tests (simulating 10x expected weight), waterproofing checks, and fire-resistance validation (meeting EN 13501-1 standards).

-

Waste Reduction: Offcuts from steel and wood are recycled into new components, while digital design software optimizes material usage—cutting waste by 65% compared to conventional builds.

2. Mobility Redefined: From Factory to Frontier

-

Containerization: A typical 20-foot container holds 1–2 small structures (e.g., 30m² office pods), while 40-foot containers accommodate larger units (up to 80m² living spaces) or multiple smaller modules. Flat-pack designs minimize volume, reducing shipping costs by 30–40%.

-

Rapid On-Site Assembly: Once delivered, a team of 4–6 workers can assemble a basic structure in 2–3 days using pre-installed connectors and alignment guides. No heavy machinery is required for flat terrain, though cranes are used for elevated or complex layouts.

-

Terrain Adaptability: Adjustable steel legs (with 0.5–1.5m height variation) stabilize units on slopes, sand, or rocky ground. For flood-prone areas, optional hydraulic lift systems raise structures above rising waters.

3. Versatility Across Scenarios: One Structure, Infinite Uses

-

Hospitality & Tourism: Glamping pods with panoramic windows, pop-up cafes with retractable roofs, and eco-lodges with integrated solar panels cater to travelers seeking unique experiences. A mountain resort in Switzerland uses modular pods to expand capacity seasonally, adding 20 units before winter and storing them in summer.

-

Commercial Spaces: Retail kiosks, office pods, and co-working hubs adapt to urban or remote settings. A tech startup in Norway operates a “mobile office park” of 10 pods, relocating the entire setup to a new city each quarter to tap into local talent.

-

Emergency Response: Disaster-relief shelters with insulated walls, water tanks, and basic sanitation systems provide immediate housing. After a 2023 earthquake in Indonesia, 500 prefab units were deployed within 10 days, offering safer alternatives to tents.

-

Remote Work & Research: Laboratories, field stations, and educational pods support scientific exploration in Antarctica or the Amazon rainforest. A marine biology team in Australia uses a modular lab with seawater filtration and satellite connectivity to study coral reefs.

-

Size: Ranges from 15m² micro-units to 200m² multi-room complexes.

-

Exteriors: Weather-resistant aluminum panels, wood-look composites, or graffiti-friendly surfaces for urban art projects.

-

Interiors: Reconfigurable walls, built-in storage, and modular furniture (e.g., fold-out beds, collapsible desks).

4. Sustainability: Building a Greener Footprint

-

Material Innovation: Panels use recycled steel (85% post-consumer content) and FSC-certified timber. Insulation combines sheep’s wool (natural, breathable) with aerogel (ultra-thin, high-performance).

-

Energy Independence: Optional solar roof panels generate 3–5 kWh daily, powering LED lighting, laptops, and small appliances. Rainwater harvesting systems collect and filter water for non-potable uses.

-

Circular Lifecycle: At end-of-life, 95% of components (steel, glass, wiring) are recyclable. Modules can be repurposed—e.g., a retired office pod becomes a garden shed or tiny home.

5. Technological Integration: Smart, Connected, Future-Ready

-

Climate Control: Sensors adjust heating/cooling based on occupancy, reducing energy use by 25%.

-

Security: Biometric locks, motion detectors, and remote monitoring via mobile apps enhance safety.

-

Connectivity: Satellite internet (for remote areas) and 5G compatibility ensure seamless communication.

-

Expandability: New modules can be added later to grow the structure—e.g., linking two office pods with a meeting room module.

6. Global Compliance: Meeting International Standards

-

Safety: ISO 9001 (quality management), EN 1090 (structural steel), and IBC (International Building Code).

-

Accessibility: ADA-compliant ramps and wide doorways for wheelchair users.

-

Localization: Units can be modified for regional needs—e.g., stronger insulation for Nordic winters or enhanced ventilation for tropical climates.

Conclusion: The Future of Global Construction

Article link:https://www.vlefooena.com/modern-mobile-prefab-structures-factory-made-for-export-anywhere-in-the-world/

No reply content