Beyond the Hanger: How We Craft Curtains That Feel Like Home

In a world where speed often overshadows substance, our factory stands as a quiet counterpoint—one where every curtain is coaxed into existence with patience, precision, and a quiet obsession for detail. Here, we don’t just sew fabric; we stitch together stories of comfort, light, and belonging. Whether you’re a homeowner dreaming of soft morning light filtering through linen, or a designer seeking a bold statement for a penthouse, our journey from raw thread to finished drape is rooted in one truth: curtains are more than window coverings—they’re the soul of a room.

The Alchemy of Fabric Selection: Where Science Meets Sensibility

Every great curtain begins with a conversation—not just with clients, but with fabric itself. Our design team spends weeks each quarter exploring global mills, touching, stretching, and testing swatches to understand their character. Is this cotton breathable enough for a sunlit Florida bedroom? Will this wool-blend hold its structure in a drafty Chicago loft? We ask these questions because we know your curtains must perform, not just please the eye.

Sustainability is woven into this process, too. Over 70% of our fabrics now carry certifications—GOTS for organic cotton, Recycled Claim Standard for post-consumer polyester—that guarantee ethical sourcing. We’ve even developed a line of “living fabrics”: Tencel™ lyocell that biodegrades at end-of-life, and hemp blends that grow faster than they wear out. “A curtain shouldn’t outlive its welcome,” jokes our lead fabricologist, Mei. “But when it does, it should leave the planet better than it found it.”

The Handcrafted Core: Machines That Assist, Never Replace

Walk our factory floor, and you’ll witness a dance between man and machine. Automated cutters slice fabric with laser accuracy, ensuring every panel matches the millimeter—no wasted inches, no uneven edges. But the magic happens next. Skilled artisans take over:

-

Hemming by Hand: Sewing machines press seams flat, but it’s Maria, with 30 years of practice, who hand-stitches the final ½-inch hem. “Machines can’t feel the weight of the fabric,” she says. “I adjust stitch length to match—light for chiffon, tight for velvet—so the hem hangs without dragging.”

-

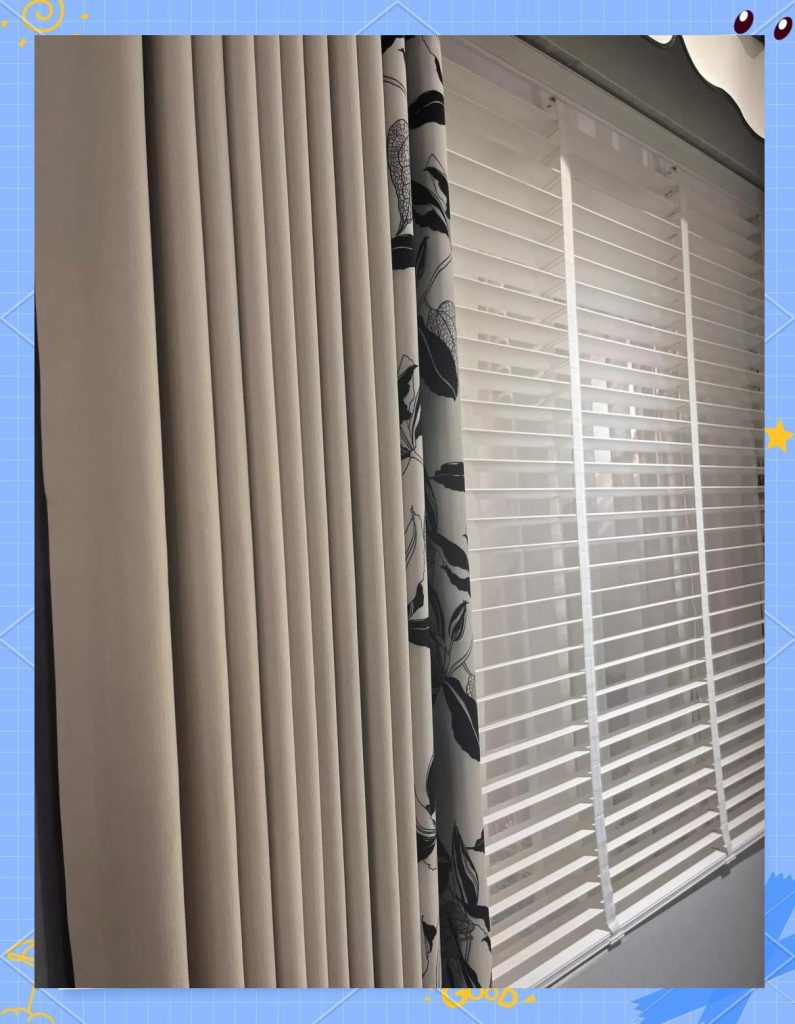

Lining as Art: Blackout linings aren’t just added; they’re fused with precision. Our team uses heat-press technology to bond layers without stiffening the drape, ensuring your room stays dark but your curtains still flow.

-

Grommet Perfection: Metal grommets are aligned with laser guides, then hand-tightened to avoid snags. “A crooked grommet ruins the line,” explains Jian, our head finisher. “We check each one twice—once for position, once for smoothness.”

These touches aren’t just “extra”—they’re what turn a curtain into a piece you notice, then forget, because it fits so seamlessly into your life.

Customization as a Dialogue: Solving Windows, Not Selling Stock

No two windows are identical, and we refuse to pretend otherwise. A recent project in a historic brownstone illustrates this: the homeowner wanted floor-to-ceiling curtains but worried about blocking original crown molding. Our team designed a retractable rod system that mounts behind the molding, paired with lightweight linen that pools just so at the floor. Another client needed curtains for a sunroom—bright, cheerful, but fade-resistant. We tested 12 dyes before landing on a solution-dyed polyester that stayed vivid even after 500 hours of UV exposure.

Our in-house design studio thrives on these puzzles. Using 3D rendering software, we let clients “place” curtains in their room virtually, tweaking colors, folds, and lengths in real time. “It’s not about pushing a catalog,” says our lead designer, Amir. “It’s about asking, ‘What does your window need to feel like home?’”

Quality That Outlasts Trends: The 10-Year Promise

In an industry where “disposable decor” is common, we stake our reputation on longevity. Every curtain undergoes a grueling 18-point quality check:

-

Wash Testing: Fabric is laundered 10 times to simulate years of use, checking for shrinkage or fading.

-

Stress Tests: Seams are tugged with industrial tools to ensure they won’t unravel.

-

Light Exposure: Panels spend 72 hours under UV lamps to guarantee color stability.

“We don’t just sell curtains,” says Carlos, our QC director. “We sell peace of mind. When you hang these, you shouldn’t have to think about them—for a decade or more.”

More Than a Factory: A Community of Care

What truly sets us apart? The people. From interns learning to thread needles beside retirees who’ve sewn here since the 1980s, to office staff who personally call clients to confirm delivery dates, we treat every order as if it’s for our own home. During last winter’s storm season, we prioritized making waterproof curtains for families in flood-prone areas—on nights and weekends, because “needs don’t wait for business hours.”

Looking ahead, we’re excited to innovate: developing curtains with built-in air-purifying fibers, or exploring biodegradable trims that decompose harmlessly. But our foundation will always be the same: a reverence for fabric, a commitment to craft, and the belief that a well-made curtain can turn a house into a haven.

So the next time you draw open a curtain and light spills across your floor, remember—behind that simple motion lies a story. A story of hands that cared, eyes that checked, and a factory that refused to cut corners.

Here, we don’t just make curtains. We make moments worth savoring.

Article link:https://www.vlefooena.com/beyond-the-hanger-how-we-craft-curtains-that-feel-like-home

No reply content