In the fast-paced world of construction, where deadlines loom and design ambitions soar, the right materials can make or break a project. Wall panels, often overlooked as mere finishes, are far more critical—they shape spaces, enhance durability, and reflect the integrity of the entire build. At our factory, we don’t just manufacture panels; we engineer solutions that bridge the gap between a client’s vision and a lasting, functional reality. Here’s how we do it.

Listening First: The Blueprint of Collaboration

Every great project starts with understanding. Before a single panel rolls off our line, we dive deep into our clients’ needs. Are they designing a sleek urban loft demanding minimalist elegance? A family home requiring child-safe, scratch-resistant surfaces? Or a commercial space needing acoustic insulation to boost productivity? Our team of project managers and material scientists collaborates closely with architects, contractors, and end-users to identify not just aesthetic preferences, but functional challenges—humidity resistance in tropical climates, fire safety codes in public buildings, or faster installation for tight schedules.

This collaborative ethos ensures no detail is missed. For example, when a regional developer sought panels for a high-traffic hospital, we worked with their team to develop a smooth, non-porous surface that withstands frequent cleaning and resists bacterial growth—critical for infection control. The result? Panels that met strict healthcare standards and aligned with the hospital’s calming, neutral design palette.

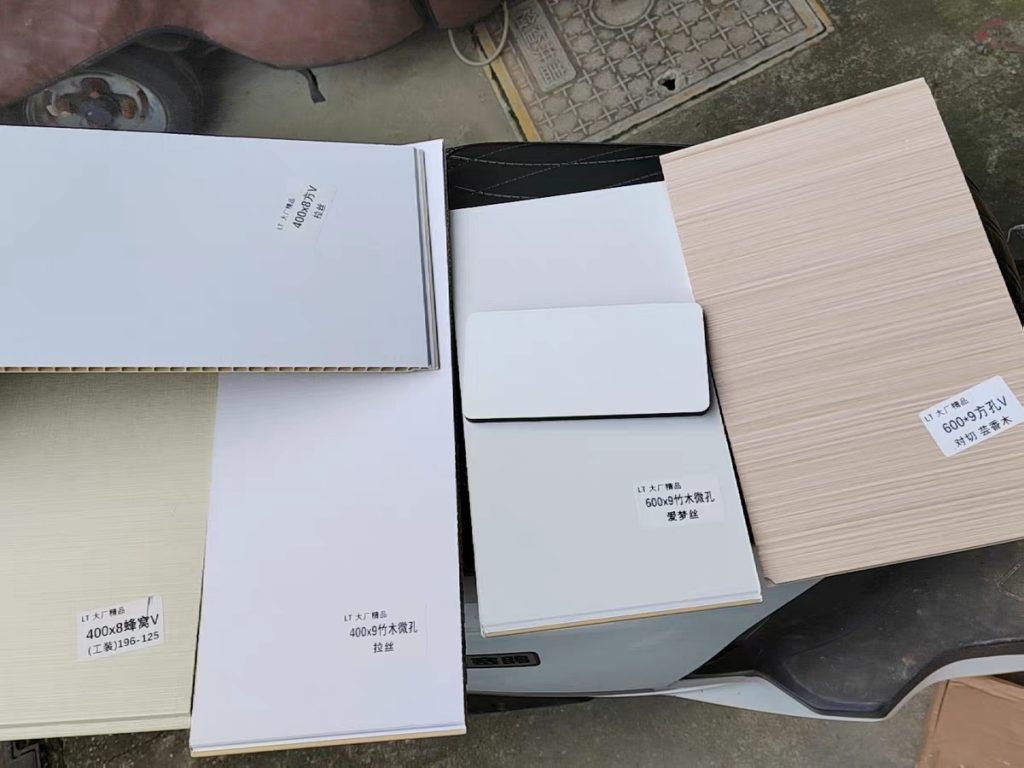

Craftsmanship Meets Technology: The Anatomy of a Premium Panel

What sets our panels apart lies in their DNA: a fusion of cutting-edge technology and hands-on expertise.

-

Material Mastery: We source only the finest inputs. For wood-based panels, we partner with FSC-certified mills to ensure sustainably harvested timber. For composites, we use high-density polyethylene (HDPE) recycled from post-consumer waste, blending it with reinforcing fibers to boost strength without sacrificing flexibility. Every batch undergoes lab testing for moisture absorption, tensile strength, and color consistency—standards that exceed industry benchmarks.

-

Precision Engineering: Our automated production lines are calibrated to micrometer precision. CNC routers carve intricate patterns, while robotic arms apply UV-cured coatings that resist fading for decades. Even the edges are milled to exact tolerances, ensuring seamless joints on-site—a detail that eliminates costly rework for installers.

-

Quality Control at Every Stage: From raw material inspection to final packaging, our panels traverse 12 checkpoints. Thermal imaging detects hidden defects, while pressure tests simulate years of wear. Only panels scoring 99.8% on our quality index leave the facility—no exceptions.

Sustainability: Embedded in Our Process, Not an Afterthought

In an industry grappling with its carbon footprint, we’ve made sustainability a non-negotiable pillar.

-

Circular Design: Over 80% of our raw materials are recycled or bio-based. Our closed-loop water system recycles 95% of production runoff, and solar panels power 40% of our facility’s energy needs.

-

Longevity = Lower Impact: Panels are engineered to last 50+ years, reducing the need for replacements. Many feature low-VOC finishes and fire-retardant additives, making them safer for occupants and easier to dispose of responsibly at end-of-life.

-

Carbon-Neutral Shipping: We optimize logistics to minimize fuel use, partnering with carriers that offset emissions through reforestation projects. For large orders, we even offer localized production hubs to cut down on transportation miles.

Your Project, Our Priority: From Order to Installation

We know construction timelines are unforgiving. That’s why we’ve streamlined every step to keep your project on track:

-

Rapid Turnarounds: With a 500,000 sq ft production capacity and strategic inventory planning, we deliver standard orders in 2–3 weeks—even during peak seasons.

-

On-Site Support: Our technical team visits job sites to assist with layout planning, ensuring panels fit flawlessly. For complex designs, we provide 3D renderings to visualize the final look.

-

Post-Installation Follow-Up: We check in post-completion to address any concerns, because our commitment doesn’t end when the last panel is hung.

Building Trust, One Panel at a Time

Over the years, our panels have graced luxury penthouses, eco-friendly schools, and everything in between. But what truly matters are the stories behind these projects: the contractor who praised our panels for eliminating on-site waste, the homeowner who gushed about their home’s warmth, the architect who called our customization “game-changing.”

These moments drive us to keep innovating—to refine our processes, explore greener materials, and push the boundaries of what wall panels can do.

Your Vision Deserves Excellence

In construction, there’s no room for compromise. Whether you’re building a weekend retreat or a landmark skyscraper, our wall panels are more than a product—they’re a promise: We’ll deliver quality, reliability, and partnership from start to finish.

Let’s create something extraordinary, together.

Article link:https://www.vlefooena.com/beyond-the-surface-how-precision-wall-panels-transform-vision-into-reality

No reply content