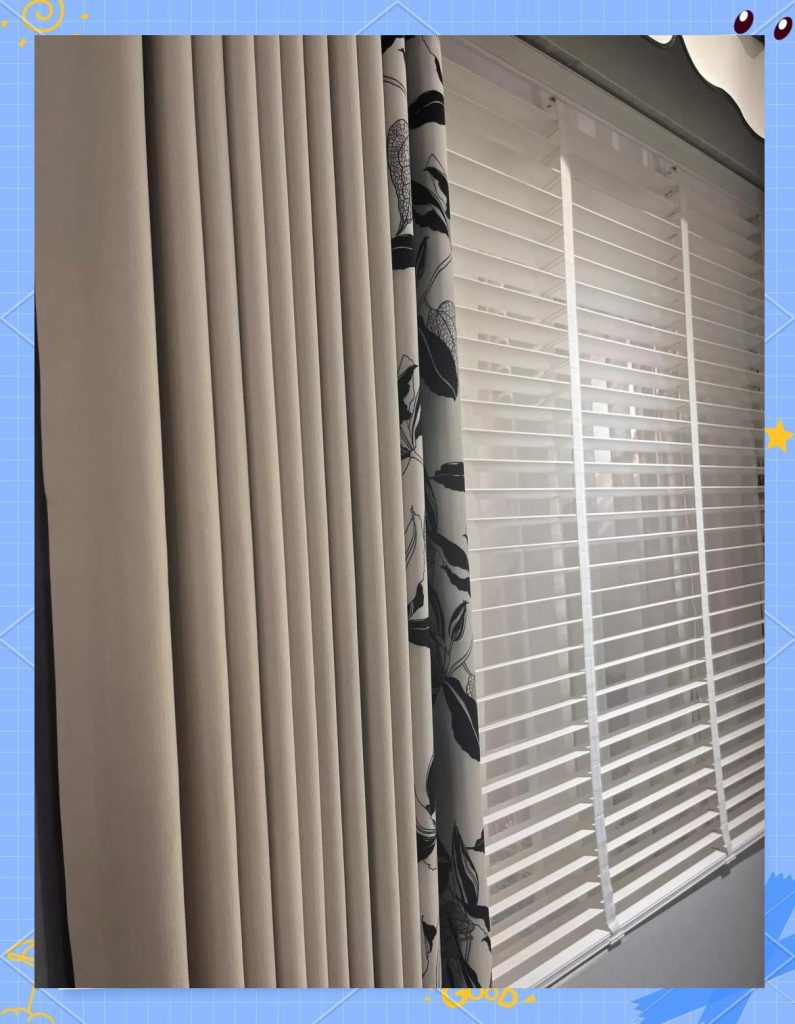

Curtains are an essential element of interior decoration, offering a perfect combination of beauty, functionality, and comfort. Behind each elegant curtain lies a detailed production process—one that reflects careful craftsmanship, precise technology, and a passion for design.

1. Fabric Selection and Material Performance

The first step in curtain manufacturing begins with selecting the right fabric. The choice of material influences the appearance, feel, and durability of the final product. Factories carefully test every fabric for color stability, light resistance, and shrinkage rate before production begins.

| Fabric Type | Composition | Main Features | Best Application | Remarks |

|---|---|---|---|---|

| Polyester | 100% or blended | Durable, easy to clean | Residential & hotel | Cost-effective |

| Cotton | Natural fiber | Soft, breathable | Living rooms, bedrooms | Requires ironing |

| Linen | Natural fiber | Elegant texture, eco-friendly | Cafés, boutiques | Slightly higher cost |

| Velvet | Polyester or cotton blend | Luxurious, thick, sound-absorbing | Theaters, hotels | Premium appearance |

| Jacquard | Woven pattern | Rich texture, decorative | Luxury interiors | Long-lasting color |

2. Cutting, Stitching, and Pleating Techniques

Once the materials are approved, the production process moves to cutting and sewing. Precision is vital at this stage to maintain consistent quality and proper curtain drop.

| Process Stage | Description | Key Quality Points | Equipment Used |

|---|---|---|---|

| Cutting | Digital measurement and cutting | Accuracy within ±1mm | Automatic cutting table |

| Stitching | Hemming and side stitching | Even tension, neat edges | High-speed sewing machine |

| Pleating | Creating uniform folds | Symmetry and spacing | Pleating press |

| Lining Attachment | Adding blackout or thermal lining | No wrinkles or misalignment | Industrial sewing unit |

| Eyelet / Hook Fixing | Final stage of curtain assembly | Firm installation | Metal punching machine |

Each production step is supervised by experienced workers, ensuring that every curtain meets export standards and customer expectations.

3. Quality Testing and Final Inspection

Before shipment, every batch undergoes strict quality control to guarantee performance, durability, and appearance.

| Test Item | Testing Method | Standard / Requirement | Result |

|---|---|---|---|

| Colorfastness | Rubbing and washing test | ISO 105-X12 | Passed |

| Shrinkage Rate | After washing 3 times | ≤ 2% | Passed |

| Seam Strength | Pull test on stitched area | ≥ 180N | Passed |

| Light Blocking | Lux measurement | 95–100% (blackout type) | Passed |

| Packaging Check | Visual inspection | Neat folding & labeling | Passed |

4. Customization and Export Services

A professional curtain manufacturer provides flexible OEM/ODM options. Clients can customize size, fabric type, pleating style, and packaging based on their local market preferences. Orders are carefully packed to ensure safe international shipping.

Common customization options include:

- Curtain width and height

- Lining materials (thermal, blackout, or sheer)

- Pleating types (pencil pleat, pinch pleat, grommet, wave fold)

- Header tape or eyelet choice

- Logo printing and barcode packaging

5. Sustainability and Responsibility

Modern factories are increasingly adopting eco-friendly practices. Using recycled polyester fibers, low-impact dyes, and energy-efficient machinery helps reduce environmental impact while maintaining top-tier product quality.

Conclusion

Curtain manufacturing is a blend of technology and artistry. From fabric testing to final packaging, every step demonstrates a commitment to excellence. Whether for residential interiors or large commercial projects, quality curtains bring both comfort and elegance—creating spaces that feel truly complete.

Article link:https://www.vlefooena.com/excellence-in-curtain-manufacturing-quality-design-and-global-standards

No reply content