The hospitality industry’s evolution toward efficiency, sustainability, and rapid deployment has positioned export-grade modular hotel pods as a game-changing solution for global markets. These self-contained units—manufactured in precision-controlled factories—offer unmatched durability, limitless customization, and streamlined logistics. Designed to meet international standards, they serve diverse applications from remote eco-tourism sites to urban pop-up hotels. Below, we explore the core pillars defining these innovative structures.

1. Factory-Built Excellence: Precision and Efficiency

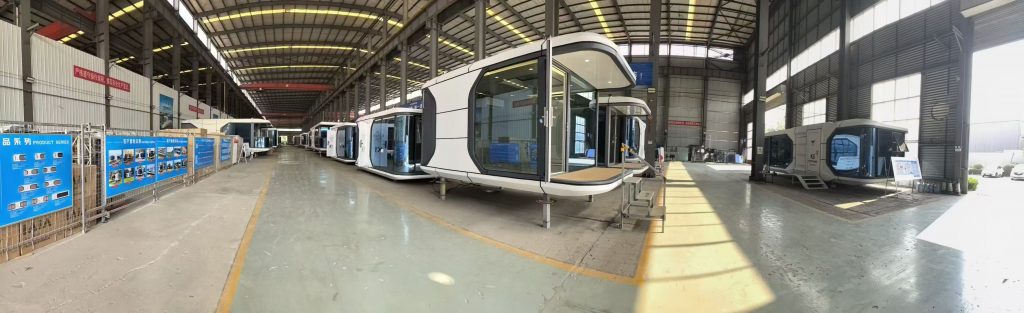

Unlike traditional construction, modular pods are assembled in climate-controlled facilities using automated systems and robotics. This method ensures zero weather-related delays and consistent quality across all units.

Key Manufacturing Advantages:

-

Structural Integrity: Galvanized steel frames with anti-corrosive coatings resist rust and seismic stress (up to 8.0 Richter scale).

-

Component Standardization: Pre-cut panels, wiring harnesses, and plumbing modules slot together seamlessly, reducing on-site labor by 75%.

-

Quality Assurance: Each pod undergoes 21-point inspections, including thermal imaging for insulation gaps and load-bearing tests.

Result: Projects deploy 50% faster than conventional builds, with near-zero material waste.

2. Engineered Durability: Built for Extreme Conditions

Export-grade pods withstand harsh climates through advanced material science and structural design.

Climate Resilience Features:

| Challenge | Solution | Performance Metric |

|---|---|---|

| Sub-zero Temperatures | Vacuum-insulated panels + heated flooring | Maintains +20°C at -30°C exterior |

| High Humidity | Marine-grade aluminum composite exteriors | Zero condensation after 5,000hr test |

| Sandstorms | Sealed joints + electrostatic dust filters | Blocks 99.7% particulates |

| Corrosive Coastlines | Fiber-reinforced polymer (FRP) cladding | Salt-spray tested for 25+ years |

Case Insight: Pods deployed in Scandinavian ski resorts operate flawlessly at -35°C, while UAE desert units maintain cool interiors at 50°C ambient temperature.

3. Limitless Customization: Tailored Experiences

Modularity enables adaptation to specific market needs without redesigning core structures.

Customization Dimensions:

-

Spatial Layouts:

-

Solo Traveler: 12m² pod with fold-down bed + desk

-

Family Unit: 22m² pod with bunk beds + kitchenette

-

Luxury Suite: 35m² pod with spa bathroom + panoramic window

-

-

Branding Integration:

-

Laser-etched logos on entry doors

-

Customizable LED accent lighting (RGBW spectrum)

-

Interchangeable façade panels (wood/stone/composite)

-

-

Tech Upgrades:

-

Solar-integrated roofing (+5kWh/day generation)

-

Greywater recycling systems (saves 40% water)

-

AI-powered HVAC with occupancy sensors

-

Example: A safari lodge operator added elevated viewing decks and wildlife-watching windows to pods, boosting bookings by 30%.

4. Sustainable Architecture: Beyond Compliance

Pods exceed global green building standards through circular design principles.

Eco-Innovations:

-

Materials:

-

85% recycled steel content

-

Cross-laminated timber (CLT) from FSC-certified forests

-

Bio-based insulation (mushroom mycelium composite)

-

-

Energy Systems:

-

Passive cooling via strategic window placement

-

Air-source heat pumps (COP 4.0 efficiency)

-

Optional Tesla Powerwall integration

-

-

End-of-Life:

-

98% recyclable components

-

Modular disassembly in <48 hours

-

Impact: A 50-unit resort achieved LEED Platinum certification with 60% lower carbon footprint vs. traditional buildings.

5. Global Deployment: Logistics Simplified

Factory-building enables seamless worldwide shipping and installation.

Supply Chain Advantages:

-

Compact Shipping: Pods flat-pack into 40ft containers (6–8 units per container)

-

Rapid Installation: Crane-ready units assemble on pre-poured foundations in <72 hours

-

Local Adaptation:

-

Adjustable base heights for flood-prone areas

-

Earthquake-dampening bearings (Japan/Chile models)

-

Tropical roof overhangs (SE Asia variants)

-

Real-World Success: A Caribbean island resort installed 120 pods in 14 days post-hurricane, providing immediate housing for displaced communities.

Conclusion: The Future of Hospitality Infrastructure

Export-grade modular hotel pods redefine what’s possible in accommodation development. By merging factory precision with rugged durability and radical customization, they offer investors turnkey solutions that slash timelines, reduce costs, and elevate guest experiences. As global travel rebounds, these pods provide the agility needed to capture emerging opportunities—from Arctic expeditions to desert festivals.

For developers seeking resilient, scalable, and planet-positive architecture, modular pods aren’t just an alternative; they’re the new standard.

Article link:https://www.vlefooena.com/export-grade-modular-hotel-pods-durable-customizable-factory-built

No reply content