The global construction industry is undergoing a transformative shift, driven by the rapid adoption of modular construction—a method that reimagines traditional building practices through precision, scalability, and sustainability. At the forefront of this revolution are prefabricated modular buildings, which are reshaping how we conceptualize, design, and deliver residential, commercial, and industrial spaces. This article explores the evolution, benefits, and future potential of modular construction, emphasizing its role in addressing global challenges such as urbanization, resource scarcity, and climate change.

1. The Evolution of Modular Construction

Modular construction, often termed “industrialized building,” involves manufacturing building components off-site in controlled environments and assembling them on-site like high-precision puzzles. This approach contrasts sharply with conventional methods, where most work occurs at the construction site. The shift is not merely procedural but philosophical—a move toward speed, scalability, and sustainability.

Historical Context:

While modular techniques date back to the early 20th century, recent advancements in technology and materials have propelled the sector into the mainstream. The 21st century has seen modular construction transition from niche applications to a cornerstone of sustainable urban development. Governments and corporations alike now prioritize modular solutions to meet stringent environmental regulations and housing demands.

Key Drivers of Adoption:

-

Urbanization: With over 60% of the global population projected to live in cities by 2030, modular construction addresses the urgent need for rapid, high-density housing.

-

Cost Efficiency: By minimizing on-site labor and material waste, modular methods reduce overall costs by up to 20% compared to traditional builds.

-

Sustainability Goals: Modular buildings often incorporate recycled materials and energy-efficient systems, aligning with global carbon-reduction targets.

2. Technological Innovations Propelling the Modular Boom

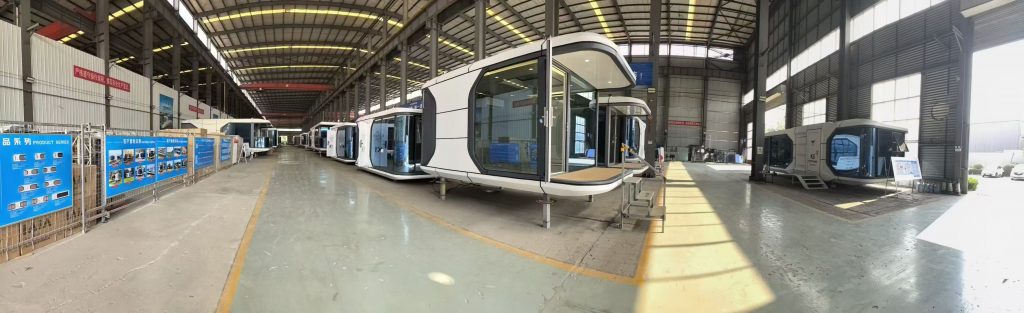

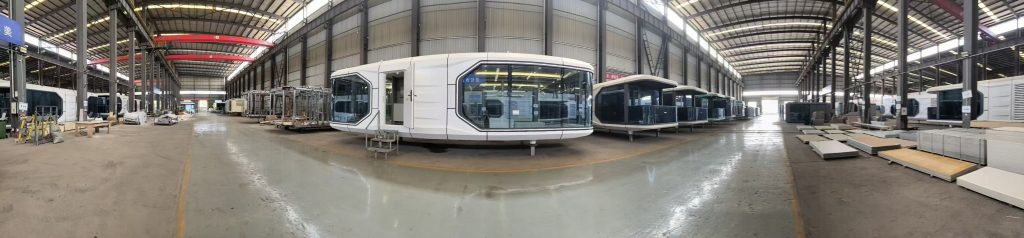

The modular sector has evolved far beyond basic container conversions. Today, it integrates cutting-edge technologies such as BIM (Building Information Modeling), robotic assembly, and smart materials to create high-performance structures.

A. Smart Design and Precision Engineering

Modern modular systems use parametric design software to optimize layouts and structural integrity. For instance, advanced algorithms enable the creation of modules tailored to extreme climates—from Arctic research stations to tropical resorts. These designs prioritize energy efficiency, with features like solar-integrated facades and rainwater recycling systems.

B. Robotic Automation

Factories now deploy robots for tasks like welding and panel assembly, reducing human error and accelerating production. Robotic arms can complete wall panel assembly in minutes, a process that once took days. This automation ensures consistency and precision, critical for achieving certifications like LEED or BREEAM.

C. Green Materials and Energy Efficiency

Modular buildings prioritize eco-friendly materials, such as cross-laminated timber (CLT) and recycled steel. Some projects incorporate self-healing concrete and photovoltaic panels, positioning them as net-zero energy solutions. For example, modular hospitals use antimicrobial coatings and advanced ventilation systems to enhance hygiene and reduce energy consumption.

3. Applications Across Industries

Modular construction’s versatility has unlocked unprecedented opportunities across diverse sectors:

A. Urban Housing and Commercial Developments

Cities facing housing shortages are turning to modular solutions. High-rises composed of prefabricated modules can be erected in months rather than years, reducing on-site labor by 60%. In commercial sectors, modular offices and retail spaces offer flexibility, allowing businesses to reconfigure layouts as needs evolve.

B. Hospitality and Tourism

Hotels and resorts leverage modular units for rapid deployment. Modular guest rooms can be installed in weeks, enabling quick responses to tourism booms. In remote areas, prefabricated lodges with zero-emission systems preserve natural landscapes while providing comfort.

C. Humanitarian and Remote Infrastructure

Modular buildings excel in disaster relief and off-grid scenarios. Post-disaster, modular schools and hospitals can be deployed within weeks. In remote regions, solar-powered modules address logistical challenges, offering sustainable solutions for energy and water access.

4. Sustainability: A Core Advantage

Modular construction’s environmental benefits are unparalleled. By manufacturing components in factories, waste is minimized—up to 90% less material is discarded compared to traditional methods. Energy consumption during production is also reduced, as factories optimize resource use through renewable energy and closed-loop systems.

Case Study Insights:

-

A modular apartment complex in Asia achieved 75% waste reduction by reusing offcuts from panel production.

-

A European hospital built with modular components reduced its carbon footprint by 40% through prefabricated steel structures.

5. Challenges and Solutions in Global Implementation

Despite its advantages, modular construction faces hurdles such as logistics, regulatory compliance, and market perception.

A. Logistics Optimization

Transporting oversized modules requires specialized equipment and route planning. Solutions include modular “packaging” that protects components during transit and partnerships with logistics firms to ensure timely delivery.

B. Regulatory Adaptation

Exporters must navigate varying building codes. For example, European markets demand compliance with strict fire ratings, while African clients prioritize corrosion resistance. Collaborative efforts between manufacturers and regulators are essential to harmonize standards.

C. Market Education

Dispelling myths about modular buildings’ “cookie-cutter” aesthetic is critical. Highlighting customizable finishes—from modular kitchens to bespoke facades—helps clients embrace the technology.

6. The Future of Modular Real Estate

The sector is poised for exponential growth, fueled by advancements in AI-driven design tools and 3D-printed modules. Emerging trends include:

-

Hybrid Modular-Traditional Hybrids: Combining prefab cores with on-site customized interiors for flexibility.

-

Circular Economy Models: Designing modules for disassembly and reuse, minimizing lifecycle waste.

-

Smart Cities Integration: Prefabricated units for smart grids, IoT-enabled infrastructure, and vertical farms.

Conclusion

Modular construction is not just a trend—it’s a fundamental reimagining of how we build for a sustainable future. By merging speed, sustainability, and scalability, prefabricated buildings are breaking down barriers in global infrastructure. As technology evolves and markets mature, this industry will likely become the cornerstone of 21st-century development, proving that innovation truly is the ultimate sustainable solution.

Article link:https://www.vlefooena.com/modular-construction-redefining-efficiency-and-sustainability-in-modern-infrastructure

No reply content